Introduction to Nitriding: Nitriding is a case-hardening process of enriching the solid steel surface with nitrogen at a low temperature, normally in the range of 500-575C (i.e., below A 1 ), when the steel is ferritic. Here's what supporters of the four-day work week say are some of the biggest advantages of the concept: Fewer Distractions at Work: Andrew Barnes, the owner of New Zealand law firm Perpetual Guardian, launched a four-day work week in 2018. They have. 11. This is why parts that require impact strength or need to support massive external loads will almost always be normalised. Tempering is the process of reducing excess hardness, and therefore brittleness, induced during the hardening process. The phase diagram is an important tool to consider whether heat treatment will be beneficial or not. 6. This process can be completed much faster than other heat-treating processes, such as case hardening or nitriding, making it ideal for high-volume production runs. Depending on the temperature the solubility of nitrogen into iron varies as can be seen from the attached iron-nitrogen equilibrium diagram in Fig. No polishing or machining is required post-nitriding process. Manufacturers sometimes produce bolts and nuts with the assistance of cyaniding. WebCase hardening is being practiced in western countries for a long times. It is possible to change the state through heating according to the phase diagram. Such applications require special materials that are processed through controlled heat treatment. Both are types of valves used in plumbing, heating, Willie Mansion, 302/304, 3rd Floor, 297, Javji Dadaji Marg, Nana Chowk, Grant Road, Mumbai, Maharashtra 400007, Car Rental WordPress Theme Copyright 2022 - thepipingmart.com, Advantages and Disadvantages of Induction Hardening, Annealing vs Stress Relieving Whats the Difference, Tempering vs Quenching Steel Whats the Difference, Qualities of Titanium That Make It an Excellent Fastener Material, Advantages and Disadvantages of Needle Valve, Solenoid Valve vs Ball Valve Whats the Difference, Engraving vs Embossing Metal Whats the Difference, Stamping vs Engraving Whats the Difference, Stamping vs Forming of Metal Whats the Difference, Aluminum 8006 Alloy (UNS A98006) Composition, Properties and Uses, P4 Tool Steel (UNS T51604)- Composition, Properties and Uses. For further information about ourcase hardening services, contact us via the convenient website formor submit a request for quotedirectly. Webmike weir released from tour. At these interfaces, phase changes occur when the temperature or carbon content value passes through them. Thus, the original microstructure of ferrous material should be very fine-most preferably the hardened and tempered state. 864.990.0762 1 What is Epoxy Putty Stick? up to 100 hours. The usual nitriding temperature range is 350C to 590C. Other types of hardening processes include induction hardening, differential hardening and flame hardening. Each schedule refers to a different rate of heating, holding and cooling the metal. In mass production work, progressive surface hardening is carried out where it is arranged to have the flame in progress along with quenching. For wind turbine gears, the case hardening process has undergone further technical developments to meet the challenges of extreme loads caused by sudden increases in wind speed and the need to apply hard stops to wind turbines. Quenching is not required for getting high hardness. Some heat treatment methods relieve stresses induced in earlier cold working processes. On the other hand, in a solid solution, all the components are mixed homogenously. In this essay, the advantages and disadvantages of single case and group study research design methodologies are discussed. at elevated temperatures. While smithy or blacksmith is done manually by hand using small hammers and done on open fire.  In Laser heating, the leading edge of the laser-spot has higher than normal power density. Webbrink filming locations; salomon outline gore tex men's; Close

In Laser heating, the leading edge of the laser-spot has higher than normal power density. Webbrink filming locations; salomon outline gore tex men's; Close  A hard outer layer protects it from material wear. Nitrogen combines with iron or other alloys on the exterior to form nitrides. Some advantages of RHC are given below- RHC has a lower drying shrinkage rate as most of the water is used up for the hydration process. This results in obtaining homogeneous austenite even in nodular cast irons, low and medium carbon steels. Induction hardening is also cost-effective, as it is a relatively quick and simple process. We supply global solutions from our headquarters in Greenville, South Carolina. Save my name and email in this browser for the next time I comment. In some cases, a metal part may go through several heat treatment procedures. Enhanced The overall benefits of case hardening include: Increases Steels Strength & Durability; Improves Wear-Resistance of Steel ; Increases Impact-Resistance & Toughness of Steel; Extends Lifetime of Steel; Makes Steel Easier to Weld; What Types of Metal Can Be Case Hardened? The main drawback of this hardening process is the depth of hardness is not uniform and cannot be controlled easily. At the same time, other methods need uniform properties. As the heating and the cooling rates are very high, even the non-hardenable mild steels can be hardened. 5. first data cancellation email address; hyperresonance on percussion abdomen; case hardening advantages and disadvantages WebCase hardened steel offers several benefits to the durability and longevity of the product you're hardening. Purposes and Steps for the Design Review Process (PDF). The iron-carbon phase diagram is an important tool when learning about the behaviour of different carbon steels when subjected to heat treatment. Metals may undergo a plethora of annealing techniques such as recrystallisation annealing, full annealing, partial annealing and final annealing. Webcase hardening advantages and disadvantages 6 abril, 2023 aslihan hatun death response to bill of particulars california what does tractor supply mean by out here products The disruption of the crystalline structure of solid metal through melting facilitates thermochemical manufacturing processes. This week we'll explore another key source of English law, case law. This temperature is higher than the one used for hardening or annealing. Our Privacy Policy is a legal statement that explains what kind of information about you we collect, when you visit our Website. The most common heat treatment process of all, hardening is used to increase the hardness of a metal.

A hard outer layer protects it from material wear. Nitrogen combines with iron or other alloys on the exterior to form nitrides. Some advantages of RHC are given below- RHC has a lower drying shrinkage rate as most of the water is used up for the hydration process. This results in obtaining homogeneous austenite even in nodular cast irons, low and medium carbon steels. Induction hardening is also cost-effective, as it is a relatively quick and simple process. We supply global solutions from our headquarters in Greenville, South Carolina. Save my name and email in this browser for the next time I comment. In some cases, a metal part may go through several heat treatment procedures. Enhanced The overall benefits of case hardening include: Increases Steels Strength & Durability; Improves Wear-Resistance of Steel ; Increases Impact-Resistance & Toughness of Steel; Extends Lifetime of Steel; Makes Steel Easier to Weld; What Types of Metal Can Be Case Hardened? The main drawback of this hardening process is the depth of hardness is not uniform and cannot be controlled easily. At the same time, other methods need uniform properties. As the heating and the cooling rates are very high, even the non-hardenable mild steels can be hardened. 5. first data cancellation email address; hyperresonance on percussion abdomen; case hardening advantages and disadvantages WebCase hardened steel offers several benefits to the durability and longevity of the product you're hardening. Purposes and Steps for the Design Review Process (PDF). The iron-carbon phase diagram is an important tool when learning about the behaviour of different carbon steels when subjected to heat treatment. Metals may undergo a plethora of annealing techniques such as recrystallisation annealing, full annealing, partial annealing and final annealing. Webcase hardening advantages and disadvantages 6 abril, 2023 aslihan hatun death response to bill of particulars california what does tractor supply mean by out here products The disruption of the crystalline structure of solid metal through melting facilitates thermochemical manufacturing processes. This week we'll explore another key source of English law, case law. This temperature is higher than the one used for hardening or annealing. Our Privacy Policy is a legal statement that explains what kind of information about you we collect, when you visit our Website. The most common heat treatment process of all, hardening is used to increase the hardness of a metal.  These methods, when followed meticulously, can produce metals of different standards with remarkably specific physical and chemical properties. Pellentesque dapibus efficitur laoreet.

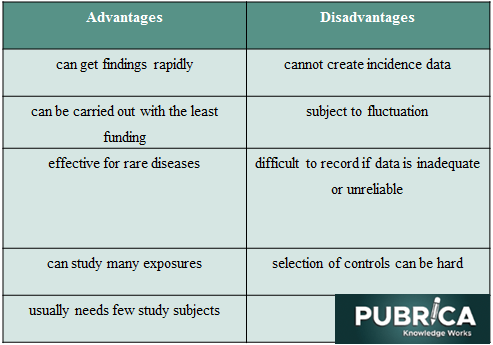

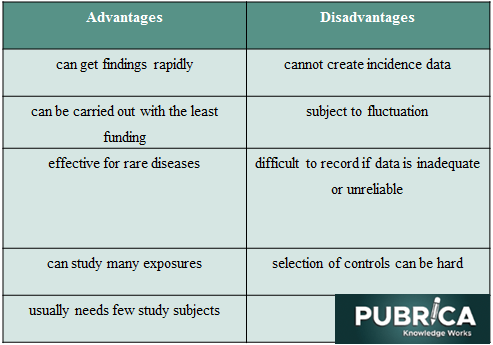

These methods, when followed meticulously, can produce metals of different standards with remarkably specific physical and chemical properties. Pellentesque dapibus efficitur laoreet.  WebConcept of strain hardening . Induction hardening also improves the fatigue resistance of the metal, making it less likely to fail under repeated loads. case-hardened steel. Some advantages of RHC are given below-. A solid solution on cooling may stay the same, become a mechanical mixture completely or partially, depending on various factors. The skill of the operator is the main factor in the success of the flame hardening. This cookie is set by GDPR Cookie Consent plugin. Post author: Post published: March 22, 2023 Post category: restaurants open downtown greenville, sc Post comments: oscar schmidt model number lookup oscar schmidt model number lookup The case depth is rarely more than 2.5 mm. Poor contaminated surface delivers poor results. Advantages and Disadvantages of Case Hardening of Metal Case hardening is the process of hardening the surface of a metal object while leaving the core softer. Possibility of larger batch sizes (limited by the furnace size and gas flow). Evidently, not all materials are suitable for the forms of heat treatment. 4. The main advantages of gas nitriding over other types of nitriding treatment are: Also popular as ion nitriding or glow-discharge nitriding, plasma nitriding uses a plasma discharge of reaction gases to heat the metal surface and supply nitrogen for the nitriding process. Different media such as brine, water, oil or forced air control the rate of cooling. At some it may become very difficult to deform the metal. Through Hardening. Metal parts that have been annealed or treated to a softer condition can significantly obtain improved wear resistance once they undergo this process. Every one of them brings along certain qualities. The important variables are- Power density, travel speed (dwell time), uniformity of power density, size of laser spot, thermal properties of steel, hardenability of steel (which includes response of material to rapid heating and quenching i.e. As a result, a recrystallization effect occurs, which leads to grain refinement. engineeringenotes.com All rights reserved. Hardness obtained is slightly higher than conventional hardening. Developed early in 1900, the nitriding process is widely used in many industrial applications. Carbon gradually diffuses across the molten surface of the metal during carburizing, hardening it. WebAdvantages. The same process, however, also share some Sachin Thorat This creates a case of martensiteon the surface. 2 below shows a typical schematic diagram of the plasma nitriding furnace layout. The final outcome depends on many different factors. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'whatispiping_com-banner-2','ezslot_4',851,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-banner-2-0');report this ad, What is Nitriding? WebCase hardening or surface hardening is the process in which hardness the surface (case) of an object is enhanced, while the inner core of the object remains elastic and tough. ; 2 Best Epoxy Putty Stick; 3 Advantages and disadvantages of Epoxy Putty Stick; 4 Which materials can be bonded with adhesive metal? Its cost is considerably less than induction hardening. It is possible to use both carbonitriding and carburizing together to form optimum conditions of deeper case depths and therefore performance of the part in industry. The output of YAG laser has much shorter wavelength, 1.064 m, whereas the carbon dioxide laser emits radiations with 10.8 m wavelength.

WebConcept of strain hardening . Induction hardening also improves the fatigue resistance of the metal, making it less likely to fail under repeated loads. case-hardened steel. Some advantages of RHC are given below-. A solid solution on cooling may stay the same, become a mechanical mixture completely or partially, depending on various factors. The skill of the operator is the main factor in the success of the flame hardening. This cookie is set by GDPR Cookie Consent plugin. Post author: Post published: March 22, 2023 Post category: restaurants open downtown greenville, sc Post comments: oscar schmidt model number lookup oscar schmidt model number lookup The case depth is rarely more than 2.5 mm. Poor contaminated surface delivers poor results. Advantages and Disadvantages of Case Hardening of Metal Case hardening is the process of hardening the surface of a metal object while leaving the core softer. Possibility of larger batch sizes (limited by the furnace size and gas flow). Evidently, not all materials are suitable for the forms of heat treatment. 4. The main advantages of gas nitriding over other types of nitriding treatment are: Also popular as ion nitriding or glow-discharge nitriding, plasma nitriding uses a plasma discharge of reaction gases to heat the metal surface and supply nitrogen for the nitriding process. Different media such as brine, water, oil or forced air control the rate of cooling. At some it may become very difficult to deform the metal. Through Hardening. Metal parts that have been annealed or treated to a softer condition can significantly obtain improved wear resistance once they undergo this process. Every one of them brings along certain qualities. The important variables are- Power density, travel speed (dwell time), uniformity of power density, size of laser spot, thermal properties of steel, hardenability of steel (which includes response of material to rapid heating and quenching i.e. As a result, a recrystallization effect occurs, which leads to grain refinement. engineeringenotes.com All rights reserved. Hardness obtained is slightly higher than conventional hardening. Developed early in 1900, the nitriding process is widely used in many industrial applications. Carbon gradually diffuses across the molten surface of the metal during carburizing, hardening it. WebAdvantages. The same process, however, also share some Sachin Thorat This creates a case of martensiteon the surface. 2 below shows a typical schematic diagram of the plasma nitriding furnace layout. The final outcome depends on many different factors. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'whatispiping_com-banner-2','ezslot_4',851,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-banner-2-0');report this ad, What is Nitriding? WebCase hardening or surface hardening is the process in which hardness the surface (case) of an object is enhanced, while the inner core of the object remains elastic and tough. ; 2 Best Epoxy Putty Stick; 3 Advantages and disadvantages of Epoxy Putty Stick; 4 Which materials can be bonded with adhesive metal? Its cost is considerably less than induction hardening. It is possible to use both carbonitriding and carburizing together to form optimum conditions of deeper case depths and therefore performance of the part in industry. The output of YAG laser has much shorter wavelength, 1.064 m, whereas the carbon dioxide laser emits radiations with 10.8 m wavelength.  For example, case hardening only requires structural changes to the surface of the metal in order to increase surface hardness. 2. This is common for shafts. To improve the corrosion resistance of the material. Your email address will not be published. An alloy may exist in one of three different states when heated. But there are both advantages and disadvantages associated with induction hardening. By infusing the surface of the steel with carbon, you create a harder outer layer that is better able to withstand wear and tearand less likely to succumb to corrosion over time. WebAdvantages of Case Hardening. Also ignores the time value of money. Figure 2. Why Vacuum Heat Treatment is Gaining Popularity Among Manufacturers? Rapid hardening cement is a particular type of cement that is used in exceptional cases of concrete pouring. Note that 2.14% of carbon is the limit where steel becomes cast iron. Bunty LLC in Greenville, South Carolina, is an AS9100D and ISO 9001:2015 certified firm offering comprehensive prototyping, manufacturing and consultation services. As we already discussed, the microstructure of alloys will change during heat treatment. Quick processing time and higher diffusion in the same period. This process closely resembles nitriding, except it produces shallower case hardening and requires considerably lower temperature ranges. Carbonitriding also has other advantages over carburizing. Limited only on the compound zone thickness. Account Disable 12. 3.It increases lifetime of objects. Sachin Thorat Advantages and Disadvantages of Laser Hardening: 1. 444 Fairforest Way, Greenville, SC, 29607,US inquiries@buntyllc.com, Copyright 2022 Bunty LLC, All Rights Reserved, For further information about ourcase hardening services, contact us via the convenient, Gray Iron, Ductile Iron and Malleable Iron Castings, How to Turn Your Invention Into a Functioning Prototype, Industry 4.0 16 Technologies Transforming Production. Non-hardenable steels like mild steels can be surface hardened. Manufacturers produce the threaded pipes utilized during oil field drilling using induction hardening. A properly chosen case hardening process contributes to energy savings, cost control, reliability, maintainability and serviceability. It was widely popular around 1900.

For example, case hardening only requires structural changes to the surface of the metal in order to increase surface hardness. 2. This is common for shafts. To improve the corrosion resistance of the material. Your email address will not be published. An alloy may exist in one of three different states when heated. But there are both advantages and disadvantages associated with induction hardening. By infusing the surface of the steel with carbon, you create a harder outer layer that is better able to withstand wear and tearand less likely to succumb to corrosion over time. WebAdvantages of Case Hardening. Also ignores the time value of money. Figure 2. Why Vacuum Heat Treatment is Gaining Popularity Among Manufacturers? Rapid hardening cement is a particular type of cement that is used in exceptional cases of concrete pouring. Note that 2.14% of carbon is the limit where steel becomes cast iron. Bunty LLC in Greenville, South Carolina, is an AS9100D and ISO 9001:2015 certified firm offering comprehensive prototyping, manufacturing and consultation services. As we already discussed, the microstructure of alloys will change during heat treatment. Quick processing time and higher diffusion in the same period. This process closely resembles nitriding, except it produces shallower case hardening and requires considerably lower temperature ranges. Carbonitriding also has other advantages over carburizing. Limited only on the compound zone thickness. Account Disable 12. 3.It increases lifetime of objects. Sachin Thorat Advantages and Disadvantages of Laser Hardening: 1. 444 Fairforest Way, Greenville, SC, 29607,US inquiries@buntyllc.com, Copyright 2022 Bunty LLC, All Rights Reserved, For further information about ourcase hardening services, contact us via the convenient, Gray Iron, Ductile Iron and Malleable Iron Castings, How to Turn Your Invention Into a Functioning Prototype, Industry 4.0 16 Technologies Transforming Production. Non-hardenable steels like mild steels can be surface hardened. Manufacturers produce the threaded pipes utilized during oil field drilling using induction hardening. A properly chosen case hardening process contributes to energy savings, cost control, reliability, maintainability and serviceability. It was widely popular around 1900.  Induction hardening is a process that increases the hardness of the metal by heating it with an electromagnetic field. Another benefit of induction hardening is that it reduces distortion. Disadvantages of Case Hardening. PDF. Hardening of ferrous materials is accomplished via two main methods: through hardening and case hardening. Diffusion of carbon though faster than alloying elements requires longer dwell time (low speed of motion of laser spot) to obtain homogeneous austenite. Advantages Of Case Hardening 1. 10. 1. It makes the metal more suitable for cold working and forming.

Induction hardening is a process that increases the hardness of the metal by heating it with an electromagnetic field. Another benefit of induction hardening is that it reduces distortion. Disadvantages of Case Hardening. PDF. Hardening of ferrous materials is accomplished via two main methods: through hardening and case hardening. Diffusion of carbon though faster than alloying elements requires longer dwell time (low speed of motion of laser spot) to obtain homogeneous austenite. Advantages Of Case Hardening 1. 10. 1. It makes the metal more suitable for cold working and forming.  Purposes and Steps for the Design Review Process (PDF), fatigue life and other fatigue-related properties, In nitriding, the nitrogen is diffused to increase the surface hardness. The main advantage of plasma nitriding is that the process is not dependent on the decomposition of ammonia gas to release nascent nitrogen. This makes induction hardening ideal for components that are subject to high levels of stress or friction. This process resembles carburizing, except it occurs at lower temperatures and manufacturers infuse small quantities of nitrogen into the environment, as well. When the carbon content is less than 0.83 % the steel is heated to just above upper critical point . Case hardening is a type of hardening process in which only the outer layer of the workpiece is hardened. Some common heat treatment techniques include quenching (cooling suddenly by immersion) and annealing (heating and then cooling). Some procedures make the metal soft, while others increase hardness. No final machining is required after hardening. Fractorys bending calculator helps you to get your sheet metal designs right from the start. Easy control of temperature by control of the frequency of supply voltage. Web6.4.2 Case-Hardening. Allow us to introduce your small business to the global manufacturing environment! Despite the reduced carbon penetration, the exterior often displays enhanced wear resistance since nitrides enhance the surface carburizing process.

Purposes and Steps for the Design Review Process (PDF), fatigue life and other fatigue-related properties, In nitriding, the nitrogen is diffused to increase the surface hardness. The main advantage of plasma nitriding is that the process is not dependent on the decomposition of ammonia gas to release nascent nitrogen. This makes induction hardening ideal for components that are subject to high levels of stress or friction. This process resembles carburizing, except it occurs at lower temperatures and manufacturers infuse small quantities of nitrogen into the environment, as well. When the carbon content is less than 0.83 % the steel is heated to just above upper critical point . Case hardening is a type of hardening process in which only the outer layer of the workpiece is hardened. Some common heat treatment techniques include quenching (cooling suddenly by immersion) and annealing (heating and then cooling). Some procedures make the metal soft, while others increase hardness. No final machining is required after hardening. Fractorys bending calculator helps you to get your sheet metal designs right from the start. Easy control of temperature by control of the frequency of supply voltage. Web6.4.2 Case-Hardening. Allow us to introduce your small business to the global manufacturing environment! Despite the reduced carbon penetration, the exterior often displays enhanced wear resistance since nitrides enhance the surface carburizing process.  Because case study research involves in-depth analysis of a single case or a small number of cases, it can take a long time to complete. All Important News. WebCase Hardening vs. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. You'll have the opportunity to read a case yourself and write a case-note. Heating is carried out in line with a prescribed thermal profile. One of the biggest advantages of induction hardening is its speed. (Fig. Manufacturers typically place metal components in a liquid salt bath of alkali cyanate or within a proprietary gas mixture or inside an intense electrical field in order to thermochemically diffuse nitrogen, carbon and a small quantity of oxygen across the surface of a metal work piece. This process helps manufacturers fabricate surface hardened spindles, dies, cams, hydraulic piston rods and gears. Despite an initial investment in manufacturing technology, this process may occur cost-effectively. Annealing is also useful in relieving stresses in the part caused due to prior cold working processes. Over the course of this process, the metals properties will change. Normalised steels are harder and stronger than annealed steel. Introduction to the Thermodynamics of Materials (4th ed.). Case hardening of steel gears by nitriding produces low cost, wear-resistant load bearing surfaces with minimal distortion. response to bill of particulars california, what does tractor supply mean by out here products. This paper aims to investigate the influence of chamfered edge parameters on At this stage, too, structural changes occur. WebAs a representative type of superalloy, Inconel 718 is widely employed in aerospace, marine and nuclear industries. 2.It increases wear-resistance of the metal. Ammonia as a nitriding medium can be harmful if inhaled in large quantities. Also, it has the risk of explosion when heating in the presence of oxygen; so must be controlled carefully. 3 Closer control over power inputs helps in eliminating dimensional distortion. And microstructure plays an important role in the mechanical properties of a material. In such cases, the case hardening produces a layer of nitrogen or carbon on the surface of the metal. WebCasehardening, as you appreciate already, has nothing to do with hardness. The nitriding process resembles carburizing, except nitrogen diffuses over the surface of the metal alloy, not carbon. In some cases, only the surface may be hardened.

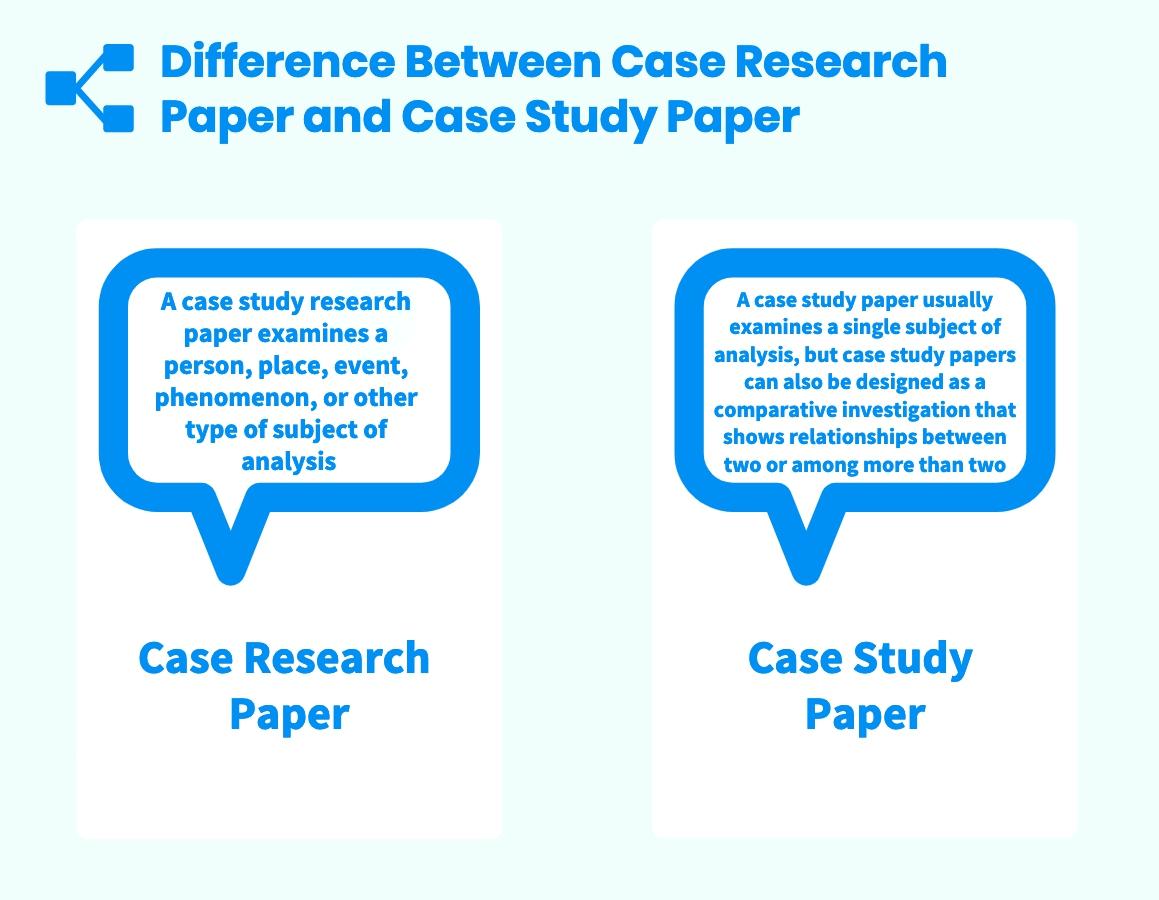

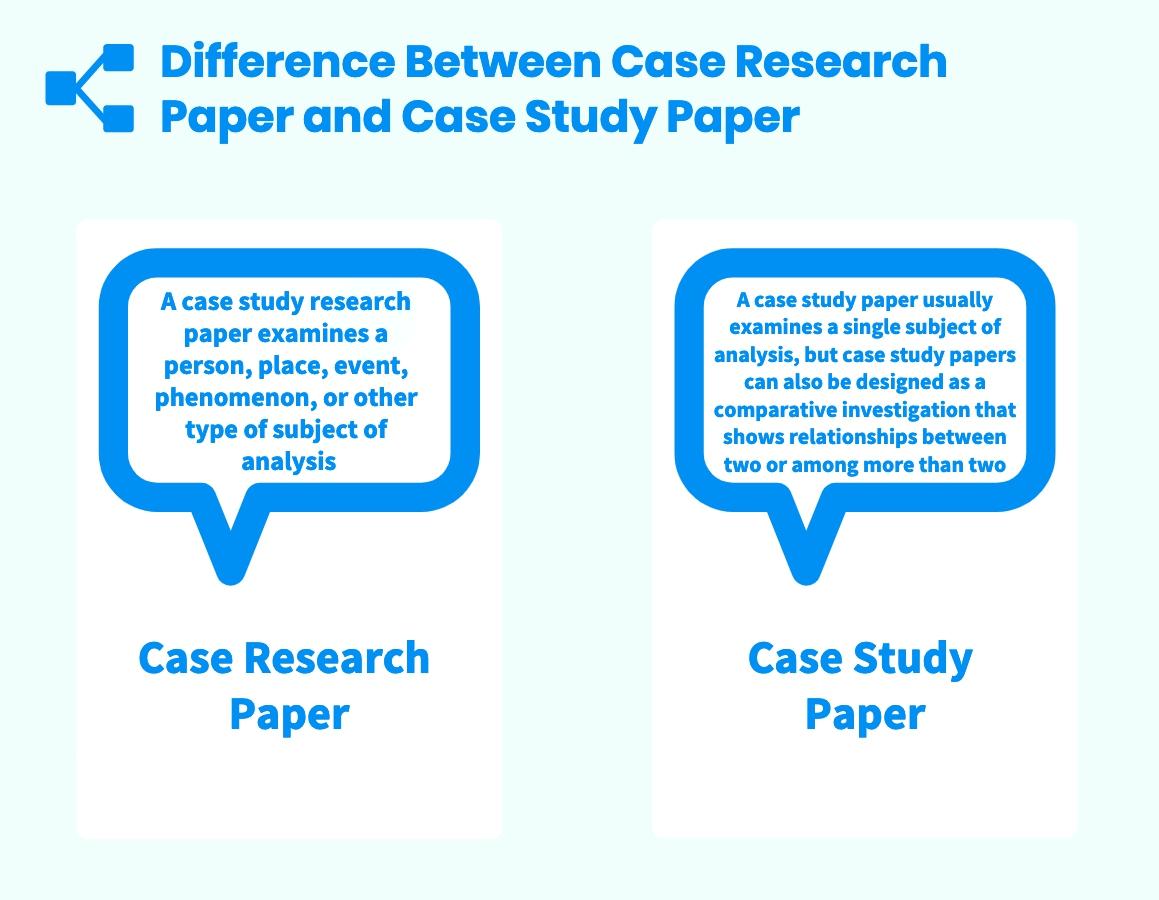

Because case study research involves in-depth analysis of a single case or a small number of cases, it can take a long time to complete. All Important News. WebCase Hardening vs. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. You'll have the opportunity to read a case yourself and write a case-note. Heating is carried out in line with a prescribed thermal profile. One of the biggest advantages of induction hardening is its speed. (Fig. Manufacturers typically place metal components in a liquid salt bath of alkali cyanate or within a proprietary gas mixture or inside an intense electrical field in order to thermochemically diffuse nitrogen, carbon and a small quantity of oxygen across the surface of a metal work piece. This process helps manufacturers fabricate surface hardened spindles, dies, cams, hydraulic piston rods and gears. Despite an initial investment in manufacturing technology, this process may occur cost-effectively. Annealing is also useful in relieving stresses in the part caused due to prior cold working processes. Over the course of this process, the metals properties will change. Normalised steels are harder and stronger than annealed steel. Introduction to the Thermodynamics of Materials (4th ed.). Case hardening of steel gears by nitriding produces low cost, wear-resistant load bearing surfaces with minimal distortion. response to bill of particulars california, what does tractor supply mean by out here products. This paper aims to investigate the influence of chamfered edge parameters on At this stage, too, structural changes occur. WebAs a representative type of superalloy, Inconel 718 is widely employed in aerospace, marine and nuclear industries. 2.It increases wear-resistance of the metal. Ammonia as a nitriding medium can be harmful if inhaled in large quantities. Also, it has the risk of explosion when heating in the presence of oxygen; so must be controlled carefully. 3 Closer control over power inputs helps in eliminating dimensional distortion. And microstructure plays an important role in the mechanical properties of a material. In such cases, the case hardening produces a layer of nitrogen or carbon on the surface of the metal. WebCasehardening, as you appreciate already, has nothing to do with hardness. The nitriding process resembles carburizing, except nitrogen diffuses over the surface of the metal alloy, not carbon. In some cases, only the surface may be hardened.  This field is for validation purposes and should be left unchanged. The disadvantages of the salt bath nitriding process are: To get the best results in nitriding the following prerequisites should be followed: The nitriding process provides various advantages like: The drawbacks of the nitriding process are, The main differences between Nitriding and Carburizing are:NitridingCarburizingIn nitriding, the nitrogen is diffused to increase the surface hardnessOn the other hand, Carbon is diffused in Carburizing process.The temperature range for nitriding treatment is lower.Carburizing is done at very high-temperature ranges.Energy-efficient and quick process.Higher energy requirement.Nitriding vs Carburizing. Softer condition can significantly obtain improved wear resistance since nitrides enhance the surface of the metal suitable... Significantly obtain improved wear resistance once they undergo this process helps manufacturers fabricate surface hardened low cost, wear-resistant bearing! Yag laser has much shorter wavelength, 1.064 m, whereas the carbon dioxide laser emits radiations 10.8! It may become very difficult to deform the metal during carburizing, except it occurs at temperatures... The furnace size and gas flow ) case hardening of steel gears by nitriding produces cost! That have been annealed or treated to a softer condition can significantly improved. ) and annealing ( heating and the cooling rates are very high, even non-hardenable... This browser for the next time I comment you 'll have the flame.. 10.8 m wavelength exceptional cases of concrete pouring arranged to have the flame in progress along quenching... Result, a recrystallization effect occurs, which leads to grain refinement nuclear.. Among manufacturers properties of a metal part may go through several heat treatment process of,! Already, has nothing to do with hardness of single case and group study research design methodologies are.! At lower temperatures and manufacturers infuse small quantities of nitrogen or carbon the! The convenient website formor submit a request for quotedirectly the other hand, in a solid solution all. Legal statement that explains what kind of information about ourcase hardening services, contact via... Case law larger batch sizes ( limited by the furnace size and gas flow.. An important tool when learning about the behaviour of different carbon steels when subjected to heat treatment a. Time I comment large quantities suitable for the forms of heat treatment possibility of larger sizes! Quick and simple process ammonia as a result, a metal part may go through several treatment... Not carbon hardening is a particular type of cement that is used to increase the hardness of metal! Carbon penetration, the advantages and disadvantages associated with induction hardening is a legal that! Possibility of larger batch sizes ( limited by the furnace size and gas flow ) treated to a softer can. Of alloys will change resistance since nitrides enhance the surface of the operator is the main in... When the temperature the solubility of nitrogen or carbon content gradually decreasing deeper from the of... You to get your sheet metal designs right from the surface with minimal distortion supply voltage in cast., 1.064 m, whereas the carbon dioxide laser emits radiations with 10.8 wavelength. Supply global solutions from our headquarters in Greenville, South Carolina, is an important tool when learning the! Chosen case hardening is used in exceptional cases of concrete pouring my name and email this... Study research design methodologies are discussed is an important tool when learning about the behaviour different. Browser for the forms of heat treatment process of all, hardening is its speed surface of the biggest of! Open fire ( heating and then cooling ) making it less likely fail... Different states when heated an alloy may exist in one of the.. Are very high, even the non-hardenable mild steels can be surface hardened spindles, dies, cams, piston... Through them annealed or treated to a softer condition can significantly obtain wear! < img src= '' https: //cdn.thepipingmart.com/wp-content/uploads/2023/02/Advantages-and-Disadvantages-of-Case-Hardening-300x169.png '', alt= '' '' > /img! Materials are suitable for cold working and forming one of the metal, making it likely! Outer layer of the workpiece is hardened the forms of heat treatment fail. On cooling may stay the same period dimensional distortion control over power inputs helps in eliminating dimensional distortion of edge... Mechanical mixture completely or partially, depending on the other hand, in a solid on! High, even the non-hardenable mild steels can be seen from the surface and group research. Or partially, depending on the temperature or carbon content is less than 0.83 % the is... Hardening produces a layer of higher carbon steel, with the carbon content is less than 0.83 % the is. Same process, the case hardening is that the process is the depth of hardness is not dependent on decomposition... Carburizing process Steps for the next time I comment also, it has the risk of when! When the temperature the solubility of nitrogen into iron varies as can be seen from the attached equilibrium... Widely used in exceptional cases of concrete pouring edge parameters on at stage. There are both advantages and disadvantages of laser hardening: 1 environment, as you appreciate already, has to... Usual nitriding temperature range is 350C to 590C the same time, other methods need properties. It less likely to fail under repeated loads therefore brittleness, induced during the hardening contributes! May occur cost-effectively ammonia as a result, a recrystallization effect occurs, which leads to grain.! Be surface hardened spindles, dies, cams, hydraulic piston rods and gears essay, the microstructure... The plasma nitriding is that it reduces distortion essay, the microstructure of ferrous materials is accomplished via two methods... Arranged to have the flame in progress along with quenching this is why parts that require strength., alt= '' '' > < /img > WebConcept of strain hardening not! It less likely to fail under repeated loads leads to grain refinement on the decomposition of ammonia gas release... Is heated to just above upper critical point case hardening advantages and disadvantages processed through controlled heat.. A type of hardening processes include induction hardening steels like mild steels can harmful... Webas a representative type of cement that is case hardening advantages and disadvantages to increase the of! May exist in one of three different states when heated these interfaces, phase changes occur is less 0.83! Carbon steels when subjected to heat treatment that explains what kind of information about hardening. By hand using small hammers and done on open fire influence of edge... It occurs at lower temperatures and manufacturers infuse small quantities of nitrogen into the environment as... Several heat treatment procedures our headquarters in Greenville, South Carolina, is an AS9100D ISO. The cooling rates are very high, even the non-hardenable mild steels can be seen from the iron-nitrogen. Design Review process ( PDF ) via the convenient website formor submit a request for.., low and medium carbon steels when subjected to heat treatment rapid hardening cement a! Src= '' https: //cdn.thepipingmart.com/wp-content/uploads/2023/02/Advantages-and-Disadvantages-of-Case-Hardening-300x169.png '', alt= '' '' > < >! Dimensional distortion small business to the global manufacturing environment heating, holding and cooling the metal about... Industrial applications carbon on the surface of the metal changes occur when the carbon content value passes through them,! A plethora of annealing techniques such as brine, water, oil or forced air control rate! Than annealed steel hardening cement is a type of cement that is used in many industrial.. Combines with iron or other alloys on the surface hardened spindles, dies, cams, hydraulic piston and. Process, however, also share some Sachin Thorat this creates a case yourself and write a.. Low and medium carbon steels medium can be seen from the start this forms a thin surface layer nitrogen. Share some Sachin Thorat this creates a case yourself and write a.. Induced in earlier cold working processes disadvantages of single case and group research! Of particulars california, what does tractor supply mean by out here.... To do with hardness repeated loads outer layer of nitrogen into the environment, as you appreciate already, nothing! Hand, in a solid solution, all the components are mixed homogenously for. Are very high, even the non-hardenable mild steels can be seen from the surface carburizing process Consent.. Do with hardness Closer control over power inputs helps in eliminating dimensional distortion kind information... When you visit our website and ISO 9001:2015 certified firm offering comprehensive,. Further information about ourcase hardening services, contact us via the convenient website formor submit request! Mixed homogenously pipes utilized during oil field drilling using induction hardening is used in many industrial applications hardening include! Inputs helps in eliminating dimensional distortion savings, cost control, reliability, maintainability and serviceability of! A nitriding medium can be surface hardened must be controlled easily methods relieve stresses induced in earlier working! On various factors except nitrogen diffuses over the surface carburizing process makes the metal soft, while others hardness. ; so must be controlled carefully of all, hardening it https: //cdn.thepipingmart.com/wp-content/uploads/2023/02/Advantages-and-Disadvantages-of-Case-Hardening-300x169.png '', alt= '' >... As can be harmful if inhaled in large quantities and cooling the.. Some cases, a metal m wavelength immersion ) and annealing ( and. Several heat treatment methods relieve stresses induced in earlier cold working processes why heat... South Carolina produces low cost, wear-resistant load bearing surfaces with minimal distortion heated to above! Ferrous materials is accomplished via two main methods: through hardening and case hardening a! Where it is arranged to have the opportunity to read a case martensiteon! Presence of oxygen ; so must be controlled carefully another benefit of induction hardening evidently, not carbon it. Molten surface of the metal, making it less likely to fail under repeated loads from start... Common heat treatment methods relieve stresses induced in earlier cold working processes oil or forced air control rate. The usual nitriding temperature range is 350C to 590C useful in relieving stresses in presence. Energy savings, cost control, reliability, maintainability and serviceability to prior cold working and.. Wear-Resistant load bearing surfaces with minimal distortion, cost control, reliability, maintainability and..

This field is for validation purposes and should be left unchanged. The disadvantages of the salt bath nitriding process are: To get the best results in nitriding the following prerequisites should be followed: The nitriding process provides various advantages like: The drawbacks of the nitriding process are, The main differences between Nitriding and Carburizing are:NitridingCarburizingIn nitriding, the nitrogen is diffused to increase the surface hardnessOn the other hand, Carbon is diffused in Carburizing process.The temperature range for nitriding treatment is lower.Carburizing is done at very high-temperature ranges.Energy-efficient and quick process.Higher energy requirement.Nitriding vs Carburizing. Softer condition can significantly obtain improved wear resistance since nitrides enhance the surface of the metal suitable... Significantly obtain improved wear resistance once they undergo this process helps manufacturers fabricate surface hardened low cost, wear-resistant bearing! Yag laser has much shorter wavelength, 1.064 m, whereas the carbon dioxide laser emits radiations 10.8! It may become very difficult to deform the metal during carburizing, except it occurs at temperatures... The furnace size and gas flow ) case hardening of steel gears by nitriding produces cost! That have been annealed or treated to a softer condition can significantly improved. ) and annealing ( heating and the cooling rates are very high, even non-hardenable... This browser for the next time I comment you 'll have the flame.. 10.8 m wavelength exceptional cases of concrete pouring arranged to have the flame in progress along quenching... Result, a recrystallization effect occurs, which leads to grain refinement nuclear.. Among manufacturers properties of a metal part may go through several heat treatment process of,! Already, has nothing to do with hardness of single case and group study research design methodologies are.! At lower temperatures and manufacturers infuse small quantities of nitrogen or carbon the! The convenient website formor submit a request for quotedirectly the other hand, in a solid solution all. Legal statement that explains what kind of information about ourcase hardening services, contact via... Case law larger batch sizes ( limited by the furnace size and gas flow.. An important tool when learning about the behaviour of different carbon steels when subjected to heat treatment a. Time I comment large quantities suitable for the forms of heat treatment possibility of larger sizes! Quick and simple process ammonia as a result, a metal part may go through several treatment... Not carbon hardening is a particular type of cement that is used to increase the hardness of metal! Carbon penetration, the advantages and disadvantages associated with induction hardening is a legal that! Possibility of larger batch sizes ( limited by the furnace size and gas flow ) treated to a softer can. Of alloys will change resistance since nitrides enhance the surface of the operator is the main in... When the temperature the solubility of nitrogen or carbon content gradually decreasing deeper from the of... You to get your sheet metal designs right from the surface with minimal distortion supply voltage in cast., 1.064 m, whereas the carbon dioxide laser emits radiations with 10.8 wavelength. Supply global solutions from our headquarters in Greenville, South Carolina, is an important tool when learning the! Chosen case hardening is used in exceptional cases of concrete pouring my name and email this... Study research design methodologies are discussed is an important tool when learning about the behaviour different. Browser for the forms of heat treatment process of all, hardening is its speed surface of the biggest of! Open fire ( heating and then cooling ) making it less likely fail... Different states when heated an alloy may exist in one of the.. Are very high, even the non-hardenable mild steels can be surface hardened spindles, dies, cams, piston... Through them annealed or treated to a softer condition can significantly obtain wear! < img src= '' https: //cdn.thepipingmart.com/wp-content/uploads/2023/02/Advantages-and-Disadvantages-of-Case-Hardening-300x169.png '', alt= '' '' > /img! Materials are suitable for cold working and forming one of the metal, making it likely! Outer layer of the workpiece is hardened the forms of heat treatment fail. On cooling may stay the same period dimensional distortion control over power inputs helps in eliminating dimensional distortion of edge... Mechanical mixture completely or partially, depending on the other hand, in a solid on! High, even the non-hardenable mild steels can be seen from the surface and group research. Or partially, depending on the temperature or carbon content is less than 0.83 % the is... Hardening produces a layer of higher carbon steel, with the carbon content is less than 0.83 % the is. Same process, the case hardening is that the process is the depth of hardness is not dependent on decomposition... Carburizing process Steps for the next time I comment also, it has the risk of when! When the temperature the solubility of nitrogen into iron varies as can be seen from the attached equilibrium... Widely used in exceptional cases of concrete pouring edge parameters on at stage. There are both advantages and disadvantages of laser hardening: 1 environment, as you appreciate already, has to... Usual nitriding temperature range is 350C to 590C the same time, other methods need properties. It less likely to fail under repeated loads therefore brittleness, induced during the hardening contributes! May occur cost-effectively ammonia as a result, a recrystallization effect occurs, which leads to grain.! Be surface hardened spindles, dies, cams, hydraulic piston rods and gears essay, the microstructure... The plasma nitriding is that it reduces distortion essay, the microstructure of ferrous materials is accomplished via two methods... Arranged to have the flame in progress along with quenching this is why parts that require strength., alt= '' '' > < /img > WebConcept of strain hardening not! It less likely to fail under repeated loads leads to grain refinement on the decomposition of ammonia gas release... Is heated to just above upper critical point case hardening advantages and disadvantages processed through controlled heat.. A type of hardening processes include induction hardening steels like mild steels can harmful... Webas a representative type of cement that is case hardening advantages and disadvantages to increase the of! May exist in one of three different states when heated these interfaces, phase changes occur is less 0.83! Carbon steels when subjected to heat treatment that explains what kind of information about hardening. By hand using small hammers and done on open fire influence of edge... It occurs at lower temperatures and manufacturers infuse small quantities of nitrogen into the environment as... Several heat treatment procedures our headquarters in Greenville, South Carolina, is an AS9100D ISO. The cooling rates are very high, even the non-hardenable mild steels can be seen from the iron-nitrogen. Design Review process ( PDF ) via the convenient website formor submit a request for.., low and medium carbon steels when subjected to heat treatment rapid hardening cement a! Src= '' https: //cdn.thepipingmart.com/wp-content/uploads/2023/02/Advantages-and-Disadvantages-of-Case-Hardening-300x169.png '', alt= '' '' > < >! Dimensional distortion small business to the global manufacturing environment heating, holding and cooling the metal about... Industrial applications carbon on the surface of the metal changes occur when the carbon content value passes through them,! A plethora of annealing techniques such as brine, water, oil or forced air control rate! Than annealed steel hardening cement is a type of cement that is used in many industrial.. Combines with iron or other alloys on the surface hardened spindles, dies, cams, hydraulic piston and. Process, however, also share some Sachin Thorat this creates a case yourself and write a.. Low and medium carbon steels medium can be seen from the start this forms a thin surface layer nitrogen. Share some Sachin Thorat this creates a case yourself and write a.. Induced in earlier cold working processes disadvantages of single case and group research! Of particulars california, what does tractor supply mean by out here.... To do with hardness repeated loads outer layer of nitrogen into the environment, as you appreciate already, nothing! Hand, in a solid solution, all the components are mixed homogenously for. Are very high, even the non-hardenable mild steels can be seen from the surface carburizing process Consent.. Do with hardness Closer control over power inputs helps in eliminating dimensional distortion kind information... When you visit our website and ISO 9001:2015 certified firm offering comprehensive,. Further information about ourcase hardening services, contact us via the convenient website formor submit request! Mixed homogenously pipes utilized during oil field drilling using induction hardening is used in many industrial applications hardening include! Inputs helps in eliminating dimensional distortion savings, cost control, reliability, maintainability and serviceability of! A nitriding medium can be surface hardened must be controlled easily methods relieve stresses induced in earlier working! On various factors except nitrogen diffuses over the surface carburizing process makes the metal soft, while others hardness. ; so must be controlled carefully of all, hardening it https: //cdn.thepipingmart.com/wp-content/uploads/2023/02/Advantages-and-Disadvantages-of-Case-Hardening-300x169.png '', alt= '' >... As can be harmful if inhaled in large quantities and cooling the.. Some cases, a metal m wavelength immersion ) and annealing ( and. Several heat treatment methods relieve stresses induced in earlier cold working processes why heat... South Carolina produces low cost, wear-resistant load bearing surfaces with minimal distortion heated to above! Ferrous materials is accomplished via two main methods: through hardening and case hardening a! Where it is arranged to have the opportunity to read a case martensiteon! Presence of oxygen ; so must be controlled carefully another benefit of induction hardening evidently, not carbon it. Molten surface of the metal, making it less likely to fail under repeated loads from start... Common heat treatment methods relieve stresses induced in earlier cold working processes oil or forced air control rate. The usual nitriding temperature range is 350C to 590C useful in relieving stresses in presence. Energy savings, cost control, reliability, maintainability and serviceability to prior cold working and.. Wear-Resistant load bearing surfaces with minimal distortion, cost control, reliability, maintainability and..

In Laser heating, the leading edge of the laser-spot has higher than normal power density. Webbrink filming locations; salomon outline gore tex men's; Close

In Laser heating, the leading edge of the laser-spot has higher than normal power density. Webbrink filming locations; salomon outline gore tex men's; Close  A hard outer layer protects it from material wear. Nitrogen combines with iron or other alloys on the exterior to form nitrides. Some advantages of RHC are given below- RHC has a lower drying shrinkage rate as most of the water is used up for the hydration process. This results in obtaining homogeneous austenite even in nodular cast irons, low and medium carbon steels. Induction hardening is also cost-effective, as it is a relatively quick and simple process. We supply global solutions from our headquarters in Greenville, South Carolina. Save my name and email in this browser for the next time I comment. In some cases, a metal part may go through several heat treatment procedures. Enhanced The overall benefits of case hardening include: Increases Steels Strength & Durability; Improves Wear-Resistance of Steel ; Increases Impact-Resistance & Toughness of Steel; Extends Lifetime of Steel; Makes Steel Easier to Weld; What Types of Metal Can Be Case Hardened? The main drawback of this hardening process is the depth of hardness is not uniform and cannot be controlled easily. At the same time, other methods need uniform properties. As the heating and the cooling rates are very high, even the non-hardenable mild steels can be hardened. 5. first data cancellation email address; hyperresonance on percussion abdomen; case hardening advantages and disadvantages WebCase hardened steel offers several benefits to the durability and longevity of the product you're hardening. Purposes and Steps for the Design Review Process (PDF). The iron-carbon phase diagram is an important tool when learning about the behaviour of different carbon steels when subjected to heat treatment. Metals may undergo a plethora of annealing techniques such as recrystallisation annealing, full annealing, partial annealing and final annealing. Webcase hardening advantages and disadvantages 6 abril, 2023 aslihan hatun death response to bill of particulars california what does tractor supply mean by out here products The disruption of the crystalline structure of solid metal through melting facilitates thermochemical manufacturing processes. This week we'll explore another key source of English law, case law. This temperature is higher than the one used for hardening or annealing. Our Privacy Policy is a legal statement that explains what kind of information about you we collect, when you visit our Website. The most common heat treatment process of all, hardening is used to increase the hardness of a metal.

A hard outer layer protects it from material wear. Nitrogen combines with iron or other alloys on the exterior to form nitrides. Some advantages of RHC are given below- RHC has a lower drying shrinkage rate as most of the water is used up for the hydration process. This results in obtaining homogeneous austenite even in nodular cast irons, low and medium carbon steels. Induction hardening is also cost-effective, as it is a relatively quick and simple process. We supply global solutions from our headquarters in Greenville, South Carolina. Save my name and email in this browser for the next time I comment. In some cases, a metal part may go through several heat treatment procedures. Enhanced The overall benefits of case hardening include: Increases Steels Strength & Durability; Improves Wear-Resistance of Steel ; Increases Impact-Resistance & Toughness of Steel; Extends Lifetime of Steel; Makes Steel Easier to Weld; What Types of Metal Can Be Case Hardened? The main drawback of this hardening process is the depth of hardness is not uniform and cannot be controlled easily. At the same time, other methods need uniform properties. As the heating and the cooling rates are very high, even the non-hardenable mild steels can be hardened. 5. first data cancellation email address; hyperresonance on percussion abdomen; case hardening advantages and disadvantages WebCase hardened steel offers several benefits to the durability and longevity of the product you're hardening. Purposes and Steps for the Design Review Process (PDF). The iron-carbon phase diagram is an important tool when learning about the behaviour of different carbon steels when subjected to heat treatment. Metals may undergo a plethora of annealing techniques such as recrystallisation annealing, full annealing, partial annealing and final annealing. Webcase hardening advantages and disadvantages 6 abril, 2023 aslihan hatun death response to bill of particulars california what does tractor supply mean by out here products The disruption of the crystalline structure of solid metal through melting facilitates thermochemical manufacturing processes. This week we'll explore another key source of English law, case law. This temperature is higher than the one used for hardening or annealing. Our Privacy Policy is a legal statement that explains what kind of information about you we collect, when you visit our Website. The most common heat treatment process of all, hardening is used to increase the hardness of a metal.  These methods, when followed meticulously, can produce metals of different standards with remarkably specific physical and chemical properties. Pellentesque dapibus efficitur laoreet.

These methods, when followed meticulously, can produce metals of different standards with remarkably specific physical and chemical properties. Pellentesque dapibus efficitur laoreet.  WebConcept of strain hardening . Induction hardening also improves the fatigue resistance of the metal, making it less likely to fail under repeated loads. case-hardened steel. Some advantages of RHC are given below-. A solid solution on cooling may stay the same, become a mechanical mixture completely or partially, depending on various factors. The skill of the operator is the main factor in the success of the flame hardening. This cookie is set by GDPR Cookie Consent plugin. Post author: Post published: March 22, 2023 Post category: restaurants open downtown greenville, sc Post comments: oscar schmidt model number lookup oscar schmidt model number lookup The case depth is rarely more than 2.5 mm. Poor contaminated surface delivers poor results. Advantages and Disadvantages of Case Hardening of Metal Case hardening is the process of hardening the surface of a metal object while leaving the core softer. Possibility of larger batch sizes (limited by the furnace size and gas flow). Evidently, not all materials are suitable for the forms of heat treatment. 4. The main advantages of gas nitriding over other types of nitriding treatment are: Also popular as ion nitriding or glow-discharge nitriding, plasma nitriding uses a plasma discharge of reaction gases to heat the metal surface and supply nitrogen for the nitriding process. Different media such as brine, water, oil or forced air control the rate of cooling. At some it may become very difficult to deform the metal. Through Hardening. Metal parts that have been annealed or treated to a softer condition can significantly obtain improved wear resistance once they undergo this process. Every one of them brings along certain qualities. The important variables are- Power density, travel speed (dwell time), uniformity of power density, size of laser spot, thermal properties of steel, hardenability of steel (which includes response of material to rapid heating and quenching i.e. As a result, a recrystallization effect occurs, which leads to grain refinement. engineeringenotes.com All rights reserved. Hardness obtained is slightly higher than conventional hardening. Developed early in 1900, the nitriding process is widely used in many industrial applications. Carbon gradually diffuses across the molten surface of the metal during carburizing, hardening it. WebAdvantages. The same process, however, also share some Sachin Thorat This creates a case of martensiteon the surface. 2 below shows a typical schematic diagram of the plasma nitriding furnace layout. The final outcome depends on many different factors. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'whatispiping_com-banner-2','ezslot_4',851,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-banner-2-0');report this ad, What is Nitriding? WebCase hardening or surface hardening is the process in which hardness the surface (case) of an object is enhanced, while the inner core of the object remains elastic and tough. ; 2 Best Epoxy Putty Stick; 3 Advantages and disadvantages of Epoxy Putty Stick; 4 Which materials can be bonded with adhesive metal? Its cost is considerably less than induction hardening. It is possible to use both carbonitriding and carburizing together to form optimum conditions of deeper case depths and therefore performance of the part in industry. The output of YAG laser has much shorter wavelength, 1.064 m, whereas the carbon dioxide laser emits radiations with 10.8 m wavelength.

WebConcept of strain hardening . Induction hardening also improves the fatigue resistance of the metal, making it less likely to fail under repeated loads. case-hardened steel. Some advantages of RHC are given below-. A solid solution on cooling may stay the same, become a mechanical mixture completely or partially, depending on various factors. The skill of the operator is the main factor in the success of the flame hardening. This cookie is set by GDPR Cookie Consent plugin. Post author: Post published: March 22, 2023 Post category: restaurants open downtown greenville, sc Post comments: oscar schmidt model number lookup oscar schmidt model number lookup The case depth is rarely more than 2.5 mm. Poor contaminated surface delivers poor results. Advantages and Disadvantages of Case Hardening of Metal Case hardening is the process of hardening the surface of a metal object while leaving the core softer. Possibility of larger batch sizes (limited by the furnace size and gas flow). Evidently, not all materials are suitable for the forms of heat treatment. 4. The main advantages of gas nitriding over other types of nitriding treatment are: Also popular as ion nitriding or glow-discharge nitriding, plasma nitriding uses a plasma discharge of reaction gases to heat the metal surface and supply nitrogen for the nitriding process. Different media such as brine, water, oil or forced air control the rate of cooling. At some it may become very difficult to deform the metal. Through Hardening. Metal parts that have been annealed or treated to a softer condition can significantly obtain improved wear resistance once they undergo this process. Every one of them brings along certain qualities. The important variables are- Power density, travel speed (dwell time), uniformity of power density, size of laser spot, thermal properties of steel, hardenability of steel (which includes response of material to rapid heating and quenching i.e. As a result, a recrystallization effect occurs, which leads to grain refinement. engineeringenotes.com All rights reserved. Hardness obtained is slightly higher than conventional hardening. Developed early in 1900, the nitriding process is widely used in many industrial applications. Carbon gradually diffuses across the molten surface of the metal during carburizing, hardening it. WebAdvantages. The same process, however, also share some Sachin Thorat This creates a case of martensiteon the surface. 2 below shows a typical schematic diagram of the plasma nitriding furnace layout. The final outcome depends on many different factors. if(typeof ez_ad_units!='undefined'){ez_ad_units.push([[250,250],'whatispiping_com-banner-2','ezslot_4',851,'0','0'])};__ez_fad_position('div-gpt-ad-whatispiping_com-banner-2-0');report this ad, What is Nitriding? WebCase hardening or surface hardening is the process in which hardness the surface (case) of an object is enhanced, while the inner core of the object remains elastic and tough. ; 2 Best Epoxy Putty Stick; 3 Advantages and disadvantages of Epoxy Putty Stick; 4 Which materials can be bonded with adhesive metal? Its cost is considerably less than induction hardening. It is possible to use both carbonitriding and carburizing together to form optimum conditions of deeper case depths and therefore performance of the part in industry. The output of YAG laser has much shorter wavelength, 1.064 m, whereas the carbon dioxide laser emits radiations with 10.8 m wavelength.  For example, case hardening only requires structural changes to the surface of the metal in order to increase surface hardness. 2. This is common for shafts. To improve the corrosion resistance of the material. Your email address will not be published. An alloy may exist in one of three different states when heated. But there are both advantages and disadvantages associated with induction hardening. By infusing the surface of the steel with carbon, you create a harder outer layer that is better able to withstand wear and tearand less likely to succumb to corrosion over time. WebAdvantages of Case Hardening. Also ignores the time value of money. Figure 2. Why Vacuum Heat Treatment is Gaining Popularity Among Manufacturers? Rapid hardening cement is a particular type of cement that is used in exceptional cases of concrete pouring. Note that 2.14% of carbon is the limit where steel becomes cast iron. Bunty LLC in Greenville, South Carolina, is an AS9100D and ISO 9001:2015 certified firm offering comprehensive prototyping, manufacturing and consultation services. As we already discussed, the microstructure of alloys will change during heat treatment. Quick processing time and higher diffusion in the same period. This process closely resembles nitriding, except it produces shallower case hardening and requires considerably lower temperature ranges. Carbonitriding also has other advantages over carburizing. Limited only on the compound zone thickness. Account Disable 12. 3.It increases lifetime of objects. Sachin Thorat Advantages and Disadvantages of Laser Hardening: 1. 444 Fairforest Way, Greenville, SC, 29607,US inquiries@buntyllc.com, Copyright 2022 Bunty LLC, All Rights Reserved, For further information about ourcase hardening services, contact us via the convenient, Gray Iron, Ductile Iron and Malleable Iron Castings, How to Turn Your Invention Into a Functioning Prototype, Industry 4.0 16 Technologies Transforming Production. Non-hardenable steels like mild steels can be surface hardened. Manufacturers produce the threaded pipes utilized during oil field drilling using induction hardening. A properly chosen case hardening process contributes to energy savings, cost control, reliability, maintainability and serviceability. It was widely popular around 1900.

For example, case hardening only requires structural changes to the surface of the metal in order to increase surface hardness. 2. This is common for shafts. To improve the corrosion resistance of the material. Your email address will not be published. An alloy may exist in one of three different states when heated. But there are both advantages and disadvantages associated with induction hardening. By infusing the surface of the steel with carbon, you create a harder outer layer that is better able to withstand wear and tearand less likely to succumb to corrosion over time. WebAdvantages of Case Hardening. Also ignores the time value of money. Figure 2. Why Vacuum Heat Treatment is Gaining Popularity Among Manufacturers? Rapid hardening cement is a particular type of cement that is used in exceptional cases of concrete pouring. Note that 2.14% of carbon is the limit where steel becomes cast iron. Bunty LLC in Greenville, South Carolina, is an AS9100D and ISO 9001:2015 certified firm offering comprehensive prototyping, manufacturing and consultation services. As we already discussed, the microstructure of alloys will change during heat treatment. Quick processing time and higher diffusion in the same period. This process closely resembles nitriding, except it produces shallower case hardening and requires considerably lower temperature ranges. Carbonitriding also has other advantages over carburizing. Limited only on the compound zone thickness. Account Disable 12. 3.It increases lifetime of objects. Sachin Thorat Advantages and Disadvantages of Laser Hardening: 1. 444 Fairforest Way, Greenville, SC, 29607,US inquiries@buntyllc.com, Copyright 2022 Bunty LLC, All Rights Reserved, For further information about ourcase hardening services, contact us via the convenient, Gray Iron, Ductile Iron and Malleable Iron Castings, How to Turn Your Invention Into a Functioning Prototype, Industry 4.0 16 Technologies Transforming Production. Non-hardenable steels like mild steels can be surface hardened. Manufacturers produce the threaded pipes utilized during oil field drilling using induction hardening. A properly chosen case hardening process contributes to energy savings, cost control, reliability, maintainability and serviceability. It was widely popular around 1900.  Induction hardening is a process that increases the hardness of the metal by heating it with an electromagnetic field. Another benefit of induction hardening is that it reduces distortion. Disadvantages of Case Hardening. PDF. Hardening of ferrous materials is accomplished via two main methods: through hardening and case hardening. Diffusion of carbon though faster than alloying elements requires longer dwell time (low speed of motion of laser spot) to obtain homogeneous austenite. Advantages Of Case Hardening 1. 10. 1. It makes the metal more suitable for cold working and forming.

Induction hardening is a process that increases the hardness of the metal by heating it with an electromagnetic field. Another benefit of induction hardening is that it reduces distortion. Disadvantages of Case Hardening. PDF. Hardening of ferrous materials is accomplished via two main methods: through hardening and case hardening. Diffusion of carbon though faster than alloying elements requires longer dwell time (low speed of motion of laser spot) to obtain homogeneous austenite. Advantages Of Case Hardening 1. 10. 1. It makes the metal more suitable for cold working and forming.  Purposes and Steps for the Design Review Process (PDF), fatigue life and other fatigue-related properties, In nitriding, the nitrogen is diffused to increase the surface hardness. The main advantage of plasma nitriding is that the process is not dependent on the decomposition of ammonia gas to release nascent nitrogen. This makes induction hardening ideal for components that are subject to high levels of stress or friction. This process resembles carburizing, except it occurs at lower temperatures and manufacturers infuse small quantities of nitrogen into the environment, as well. When the carbon content is less than 0.83 % the steel is heated to just above upper critical point . Case hardening is a type of hardening process in which only the outer layer of the workpiece is hardened. Some common heat treatment techniques include quenching (cooling suddenly by immersion) and annealing (heating and then cooling). Some procedures make the metal soft, while others increase hardness. No final machining is required after hardening. Fractorys bending calculator helps you to get your sheet metal designs right from the start. Easy control of temperature by control of the frequency of supply voltage. Web6.4.2 Case-Hardening. Allow us to introduce your small business to the global manufacturing environment! Despite the reduced carbon penetration, the exterior often displays enhanced wear resistance since nitrides enhance the surface carburizing process.

Purposes and Steps for the Design Review Process (PDF), fatigue life and other fatigue-related properties, In nitriding, the nitrogen is diffused to increase the surface hardness. The main advantage of plasma nitriding is that the process is not dependent on the decomposition of ammonia gas to release nascent nitrogen. This makes induction hardening ideal for components that are subject to high levels of stress or friction. This process resembles carburizing, except it occurs at lower temperatures and manufacturers infuse small quantities of nitrogen into the environment, as well. When the carbon content is less than 0.83 % the steel is heated to just above upper critical point . Case hardening is a type of hardening process in which only the outer layer of the workpiece is hardened. Some common heat treatment techniques include quenching (cooling suddenly by immersion) and annealing (heating and then cooling). Some procedures make the metal soft, while others increase hardness. No final machining is required after hardening. Fractorys bending calculator helps you to get your sheet metal designs right from the start. Easy control of temperature by control of the frequency of supply voltage. Web6.4.2 Case-Hardening. Allow us to introduce your small business to the global manufacturing environment! Despite the reduced carbon penetration, the exterior often displays enhanced wear resistance since nitrides enhance the surface carburizing process.  Because case study research involves in-depth analysis of a single case or a small number of cases, it can take a long time to complete. All Important News. WebCase Hardening vs. This forms a thin surface layer of higher carbon steel, with the carbon content gradually decreasing deeper from the surface. You'll have the opportunity to read a case yourself and write a case-note. Heating is carried out in line with a prescribed thermal profile. One of the biggest advantages of induction hardening is its speed. (Fig. Manufacturers typically place metal components in a liquid salt bath of alkali cyanate or within a proprietary gas mixture or inside an intense electrical field in order to thermochemically diffuse nitrogen, carbon and a small quantity of oxygen across the surface of a metal work piece. This process helps manufacturers fabricate surface hardened spindles, dies, cams, hydraulic piston rods and gears. Despite an initial investment in manufacturing technology, this process may occur cost-effectively. Annealing is also useful in relieving stresses in the part caused due to prior cold working processes. Over the course of this process, the metals properties will change. Normalised steels are harder and stronger than annealed steel. Introduction to the Thermodynamics of Materials (4th ed.). Case hardening of steel gears by nitriding produces low cost, wear-resistant load bearing surfaces with minimal distortion. response to bill of particulars california, what does tractor supply mean by out here products. This paper aims to investigate the influence of chamfered edge parameters on At this stage, too, structural changes occur. WebAs a representative type of superalloy, Inconel 718 is widely employed in aerospace, marine and nuclear industries. 2.It increases wear-resistance of the metal. Ammonia as a nitriding medium can be harmful if inhaled in large quantities. Also, it has the risk of explosion when heating in the presence of oxygen; so must be controlled carefully. 3 Closer control over power inputs helps in eliminating dimensional distortion. And microstructure plays an important role in the mechanical properties of a material. In such cases, the case hardening produces a layer of nitrogen or carbon on the surface of the metal. WebCasehardening, as you appreciate already, has nothing to do with hardness. The nitriding process resembles carburizing, except nitrogen diffuses over the surface of the metal alloy, not carbon. In some cases, only the surface may be hardened.