During browning, proteins combine with plant sugars to form a brown lignin-like compound. Copyright 1995-document.write(new Date().getFullYear()) Match silo sizes to feeding rates that keep the silage surface fresh, feed silage immediately after removing it from storage, and clean uneaten feed out of bunks each day. Wet crop material typically contains low levels of carbohydrate. The early drop in pH also limits the activity of plant enzymes that break down proteins. Therefore, when a crop is harvested as silage, the farmer is usually committed to feeding it to livestock. Propionic acid may be added to silage at the feed bunk, but application at ensiling is more effective at extending bunk life.  Exposure to oxygen any time after normal fermentation is complete allows the growth of yeasts and molds that spoil silage. Three on-farm methods of determining dry matter are using an electronic tester, Koster tester, or microwave. . Source: Heinrichs, et al. For example the silo is 50 feet long by 30 feet wide and the silage averages 12 feet deep. Particle size recommendations may need to be altered based on silo type. Sugar butyric acid + carbon dioxide + hydrogen gasLactic acid butyric acid + carbon dioxide + hydrogen gasAmino acids (alanine + glycine) + water acetic acid + ammonia. The effect of inoculating alfalfa silage with Lactobacillus plantarum MTD1 in liquid or dry form on pH. Mowing around the silo may discourage rodents. Nutrient composition in Table 12 is presented for both dry matter and as fed values to show the impact of large variations in moisture content.

Exposure to oxygen any time after normal fermentation is complete allows the growth of yeasts and molds that spoil silage. Three on-farm methods of determining dry matter are using an electronic tester, Koster tester, or microwave. . Source: Heinrichs, et al. For example the silo is 50 feet long by 30 feet wide and the silage averages 12 feet deep. Particle size recommendations may need to be altered based on silo type. Sugar butyric acid + carbon dioxide + hydrogen gasLactic acid butyric acid + carbon dioxide + hydrogen gasAmino acids (alanine + glycine) + water acetic acid + ammonia. The effect of inoculating alfalfa silage with Lactobacillus plantarum MTD1 in liquid or dry form on pH. Mowing around the silo may discourage rodents. Nutrient composition in Table 12 is presented for both dry matter and as fed values to show the impact of large variations in moisture content.  Although these bacteria do produce propionic acid and may improve bunk life, they do not survive in highly acidic silage. Therefore, transportation costs often limit the distance silage can be moved. The increased acidity also helps to limit the growth of undesirable organisms as silage ferments. For this reason, inoculants applied at the chopper tend to be more evenly distributed than those applied in a wagon or directly in the silo. Therefore, growth of clostridia increases losses of digestible dry matter and produces sour-smelling silage with low nutritional value and limited palatability. Dry matter recovery was improved at greater depths, but losses still exceeded 25 percent.

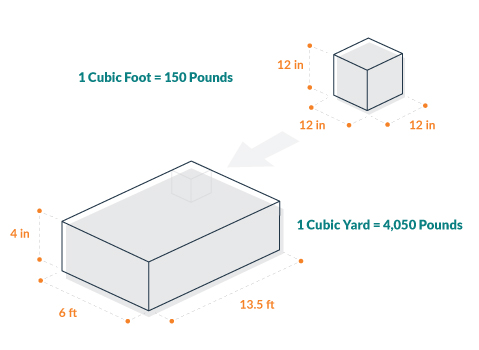

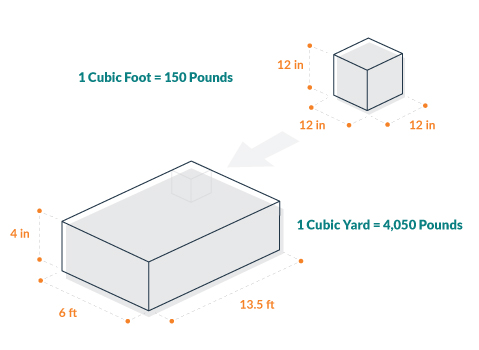

Although these bacteria do produce propionic acid and may improve bunk life, they do not survive in highly acidic silage. Therefore, transportation costs often limit the distance silage can be moved. The increased acidity also helps to limit the growth of undesirable organisms as silage ferments. For this reason, inoculants applied at the chopper tend to be more evenly distributed than those applied in a wagon or directly in the silo. Therefore, growth of clostridia increases losses of digestible dry matter and produces sour-smelling silage with low nutritional value and limited palatability. Dry matter recovery was improved at greater depths, but losses still exceeded 25 percent.  How can the total weight of a loaded forage box be estimated? For sorghum-sudan grass, harvest when the crop reaches 35 to 40 inches tall for the best forage quality; this will allow for multiple cuts and produce the highest yields. Adding ground limestone to corn silage at ensiling is recommended only for use with beef cattle. The increased acidity of the forage mass enhances the growth and development of lactic acid-producing bacteria that convert plant carbohydrates to lactic acid, acetic acid, ethanol, mannitol, and carbon dioxide. Run the blower for 15 to 20 minutes before entering the silo, and while anyone is working in it, to evacuate gas. To pack silage safely, keep a respectable distance from unsupported edges, use tractors with a rollover protection system, and wear a seat belt. Feeding strategies for high-nitrate forage include: Due to large variations in forage nitrate levels, it is important to retest forage periodically. It also should have higher lactic acid levels and a lower pH. In Imperial or US customary measurement system, the density is equal to 49.32 pound per cubic foot [lb/ft], or 0.457 ounce per cubic inch [oz/inch] . Table 10. Goggles and rubber gloves are needed to provide eye and skin protection when connecting ammonia hoses and fittings. At the boot stage, forage yield is greater than any previous stage, and the whole plant is very leafy and highly digestible. Also inspect hydraulic hoses and fittings; replace any that are leaking, stiff, cracked, or have a soft or blistered cover. Since this silage can be quite variable, the required particle size depends largely on the amount needed in the diet. However, if the time between chopping and ensiling exceeds 2 to 3 hours, inoculants should be added at the chopper. 0000028236 00000 n

If the mixer must operate while loading, add forages last. Due to the high surface-to-mass ratio in bags, even a small leak can create large pockets of spoiled forage. Silage: Field to Feedbunk. High levels of naturally occurring bacteria in silage make it difficult for inoculated bacteria to gain a competitive edge. Recommended removal rates are presented in Table 18. Therefore, the longer cut forage lies in the field, the greater respiration losses will be. Managing silage stacks or piles is similar to managing horizontal silos. Bushels = 0.314 x diameter x diameter x average depth of grain (all in feet) for ear corn, Bushels = width x length x average depth of grain (all in feet) x density (same values as previous), Bushels = Pi x diameter x diameter x depth of grain (all in feet) x density x (1 - % moisture) / .845, for number 2 shelled corn or ground ear corn It's not an everyday problem, but there will be times when you need to calculate the capacity of something. Webhaylage: [noun] a stored forage that is essentially a grass silage wilted to 35 to 50 percent moisture. Ammonia can decrease this protein degradation by 20 to 40 percent. 2Survey of research published in the United States from 1996 through July 2003. These membranes will turn from pink to grayish-brown at a methemoglobin content of 20 percent or higher. The latter accounts for the largest change. Connect with your County Extension Office , Find an Extension employee in our staff directory , Get the latest news and updates on Extension's work around the state, Feedback, questions or accessibility issues: info@extension.wisc.edu | 2023 The Board of Regents of the University of Wisconsin System Privacy Policy | Non-Discrimination Policy & How to File a Complaint | Disability Accommodation Requests. Include nitrate intake from all sources in total dietary intake. Maximum single meal dry matter intake of forages containing various levels of nitrate-nitrogen (NO3-N).1. Weight = gallons x pounds per gallon Dry matter yield of small grain forage as maturity advances. Tips useful in hot weather include: feed multiple times per day, limit wet ingredients in the ration, mix TMR for one feeding (do not mix ahead), and add a buffered propionic acid product or other mold inhibitor to the TMR where spoilage is a problem. Usually when the milk line has descended three-quarters to all the way down the corn kernel and reached the black layer stage, the moisture content is in the 55 to 60 percent range. Producers can decide late in the growing season how much corn to harvest as silage or as grain. In general, haylage has a moisture content of between 15 percent to a maximum of 40 percent (60 to 85 percent DM). To meet the guidelines presented in Table 4, it is necessary to test forage samples to determine moisture content prior to harvest. Considerable research has been conducted on the use of silage additives; however, due to the dynamic nature of silage fermentation, the results have been variable. As has been well documented by research, storage losses can range from below 5 percent to over 50 percent, depending on storage method. Due to the corrosive nature of propionic acid, it is often sold in buffered form, as a propionic salt. Table 11. Notice that yield is much greater at the soft dough stage, but silage nutrient composition is similar for boot and soft dough. From Harvest to Feed: Understanding Silage Management, Skip to the beginning of the images gallery, downloaded from the University of Wisconsin website, Effects of Calf Feeding Program on First Lactation Performance, Body Condition Scoring as a Tool for Dairy Herd Management, Colostrum Management Tools: Hydrometers and Refractometers. If harvest stretches out over an extended period, nutrient and moisture content can change drastically. Recommended moisture content of silage crops by storage structure. As legumes and grasses mature, the proportion of leaves to stems shifts away from leaves toward more stems. No. Mixing a TMR reduces the particle size of all feeds, and the length of time the ration is mixed can greatly influence particle size. 1Increase these rates for silage with dry matter density less than 14 lb/ft3 (bulk density less than 40 lb/ft3). The combination of low sugar content at harvest and high buffering capacity means alfalfa is especially prone to incomplete fermentation. When ensiling this mixture, harvest when the sudangrass is at early head to early bloom stages. Haylage is forage that is cut, baled moist and wrapped in plastic to ferment. Density = 10 to 14 pounds per cubic foot for hay Legume crops, such as alfalfa, contain relatively low levels of carbohydrates compared to corn silage and require field wilting to increase the concentration of carbohydrates and reduce moisture content in the forage mass. These products usually contain a combination of acids, including benzoic, sorbic, acetic, or citric acids, but propionic acid typically is the primary ingredient due to its excellent ability to inhibit the growth of yeast and molds. Chlorinated water may reduce the effectiveness of microbial inoculation, particularly when chlorine levels exceed 1.5 parts per million. Anhydrous ammonia is often the most economical source of ammonia or NPN. Research at The University of Wisconsin and Cornell identified a significant advantage for bunker silos with a density pack greater than 14 pounds of dry matter per cubic foot of silage.

How can the total weight of a loaded forage box be estimated? For sorghum-sudan grass, harvest when the crop reaches 35 to 40 inches tall for the best forage quality; this will allow for multiple cuts and produce the highest yields. Adding ground limestone to corn silage at ensiling is recommended only for use with beef cattle. The increased acidity of the forage mass enhances the growth and development of lactic acid-producing bacteria that convert plant carbohydrates to lactic acid, acetic acid, ethanol, mannitol, and carbon dioxide. Run the blower for 15 to 20 minutes before entering the silo, and while anyone is working in it, to evacuate gas. To pack silage safely, keep a respectable distance from unsupported edges, use tractors with a rollover protection system, and wear a seat belt. Feeding strategies for high-nitrate forage include: Due to large variations in forage nitrate levels, it is important to retest forage periodically. It also should have higher lactic acid levels and a lower pH. In Imperial or US customary measurement system, the density is equal to 49.32 pound per cubic foot [lb/ft], or 0.457 ounce per cubic inch [oz/inch] . Table 10. Goggles and rubber gloves are needed to provide eye and skin protection when connecting ammonia hoses and fittings. At the boot stage, forage yield is greater than any previous stage, and the whole plant is very leafy and highly digestible. Also inspect hydraulic hoses and fittings; replace any that are leaking, stiff, cracked, or have a soft or blistered cover. Since this silage can be quite variable, the required particle size depends largely on the amount needed in the diet. However, if the time between chopping and ensiling exceeds 2 to 3 hours, inoculants should be added at the chopper. 0000028236 00000 n

If the mixer must operate while loading, add forages last. Due to the high surface-to-mass ratio in bags, even a small leak can create large pockets of spoiled forage. Silage: Field to Feedbunk. High levels of naturally occurring bacteria in silage make it difficult for inoculated bacteria to gain a competitive edge. Recommended removal rates are presented in Table 18. Therefore, the longer cut forage lies in the field, the greater respiration losses will be. Managing silage stacks or piles is similar to managing horizontal silos. Bushels = 0.314 x diameter x diameter x average depth of grain (all in feet) for ear corn, Bushels = width x length x average depth of grain (all in feet) x density (same values as previous), Bushels = Pi x diameter x diameter x depth of grain (all in feet) x density x (1 - % moisture) / .845, for number 2 shelled corn or ground ear corn It's not an everyday problem, but there will be times when you need to calculate the capacity of something. Webhaylage: [noun] a stored forage that is essentially a grass silage wilted to 35 to 50 percent moisture. Ammonia can decrease this protein degradation by 20 to 40 percent. 2Survey of research published in the United States from 1996 through July 2003. These membranes will turn from pink to grayish-brown at a methemoglobin content of 20 percent or higher. The latter accounts for the largest change. Connect with your County Extension Office , Find an Extension employee in our staff directory , Get the latest news and updates on Extension's work around the state, Feedback, questions or accessibility issues: info@extension.wisc.edu | 2023 The Board of Regents of the University of Wisconsin System Privacy Policy | Non-Discrimination Policy & How to File a Complaint | Disability Accommodation Requests. Include nitrate intake from all sources in total dietary intake. Maximum single meal dry matter intake of forages containing various levels of nitrate-nitrogen (NO3-N).1. Weight = gallons x pounds per gallon Dry matter yield of small grain forage as maturity advances. Tips useful in hot weather include: feed multiple times per day, limit wet ingredients in the ration, mix TMR for one feeding (do not mix ahead), and add a buffered propionic acid product or other mold inhibitor to the TMR where spoilage is a problem. Usually when the milk line has descended three-quarters to all the way down the corn kernel and reached the black layer stage, the moisture content is in the 55 to 60 percent range. Producers can decide late in the growing season how much corn to harvest as silage or as grain. In general, haylage has a moisture content of between 15 percent to a maximum of 40 percent (60 to 85 percent DM). To meet the guidelines presented in Table 4, it is necessary to test forage samples to determine moisture content prior to harvest. Considerable research has been conducted on the use of silage additives; however, due to the dynamic nature of silage fermentation, the results have been variable. As has been well documented by research, storage losses can range from below 5 percent to over 50 percent, depending on storage method. Due to the corrosive nature of propionic acid, it is often sold in buffered form, as a propionic salt. Table 11. Notice that yield is much greater at the soft dough stage, but silage nutrient composition is similar for boot and soft dough. From Harvest to Feed: Understanding Silage Management, Skip to the beginning of the images gallery, downloaded from the University of Wisconsin website, Effects of Calf Feeding Program on First Lactation Performance, Body Condition Scoring as a Tool for Dairy Herd Management, Colostrum Management Tools: Hydrometers and Refractometers. If harvest stretches out over an extended period, nutrient and moisture content can change drastically. Recommended moisture content of silage crops by storage structure. As legumes and grasses mature, the proportion of leaves to stems shifts away from leaves toward more stems. No. Mixing a TMR reduces the particle size of all feeds, and the length of time the ration is mixed can greatly influence particle size. 1Increase these rates for silage with dry matter density less than 14 lb/ft3 (bulk density less than 40 lb/ft3). The combination of low sugar content at harvest and high buffering capacity means alfalfa is especially prone to incomplete fermentation. When ensiling this mixture, harvest when the sudangrass is at early head to early bloom stages. Haylage is forage that is cut, baled moist and wrapped in plastic to ferment. Density = 10 to 14 pounds per cubic foot for hay Legume crops, such as alfalfa, contain relatively low levels of carbohydrates compared to corn silage and require field wilting to increase the concentration of carbohydrates and reduce moisture content in the forage mass. These products usually contain a combination of acids, including benzoic, sorbic, acetic, or citric acids, but propionic acid typically is the primary ingredient due to its excellent ability to inhibit the growth of yeast and molds. Chlorinated water may reduce the effectiveness of microbial inoculation, particularly when chlorine levels exceed 1.5 parts per million. Anhydrous ammonia is often the most economical source of ammonia or NPN. Research at The University of Wisconsin and Cornell identified a significant advantage for bunker silos with a density pack greater than 14 pounds of dry matter per cubic foot of silage.  Feedback, questions or accessibility issues: Making Sure Your Kernel Processor Is Doing Its Job, 2023 The Board of Regents of the University of Wisconsin System, Non-Discrimination Policy & How to File a Complaint. First, calculate the amount of N needed per ton by multiplying 0.15 by the silage dry matter content as a whole number. WebDensity = 10 to 14 pounds per cubic foot for hay Density = 6 to 8 pounds per cubic foot for straw Density = 10 to 12 pounds per cubic foot for corn stover Short version: Pounds = 0.0005787 x length x width x height (all in inches) x density 8. 50 (ft) x 30 (ft) x 12 (ft) = 18,000 cubic feet 18,000 cubic feet x 40 lb/cubic feet = 720,000 lb silage Density = 4 to 5 pounds per cubic foot for straw, Pounds = 3.1416 x ( diameter / 12) x ( diameter / 12) x (width / 12) (all in inches) x density Although some natural compaction occurs in deep horizontal silos, thorough mechanical packing is required to achieve adequate density and limit excess air infiltration. Ensiling generally reduces the risk of prussic acid poisoning after about 4 weeks. As a result, fiber and lignin levels in the whole plant increase, while protein and energy decrease (Figure 3). Previous How much space does a cow need in a shed that allows them to go in The actual chemical and physical characteristics of the plant material at harvest determine the outcome of using silage additives. Microbial inoculants may be more effective when corn is immature, overly dry, stressed by drought, or killed by frost. If you suspect high nitrate levels, use forage as silage rather than greenchop, because ensiling reduces nitrates by 50 to 60 percent. The site must drain away from the open end of the bag, and should be clean and weed-free to minimize rodent populations. Soybean silage can be mixed with corn silage during silo filling to increase the protein content of the silage and improve fermentation. 1If one forage contains over 0.44% NO3 or 1,000 ppm NO3-N, test all forages, water, and possibly concentrates. 0000006582 00000 n

Web1 Capacity based on 16 lbs. Koster testers and microwaves are both used to dry a forage sample. 50 (ft) x 30 (ft) x 12 (ft) = 18,000 cubic feet 18,000 cubic feet x 40 lb/cubic feet = 720,000 lb silage Heating soon after ensiling also can lead to Maillard browning, which lowers protein quality and digestibility. Source: Nutrient Requirements of Dairy Cattle. Typical fermentation profile of, mixed mostly grass, silage at various dry matter (DM) contents. Alternatively, organic acids may be used at the rate of 10 to 20 pounds per ton to aid in preservation. Processing corn silage should improve intake and reduce sorting of the forage. Silage with incomplete fermentation due to forage containing too little carbohydrate, cold environmental conditions at harvest, or poor packing often has high pH.

Feedback, questions or accessibility issues: Making Sure Your Kernel Processor Is Doing Its Job, 2023 The Board of Regents of the University of Wisconsin System, Non-Discrimination Policy & How to File a Complaint. First, calculate the amount of N needed per ton by multiplying 0.15 by the silage dry matter content as a whole number. WebDensity = 10 to 14 pounds per cubic foot for hay Density = 6 to 8 pounds per cubic foot for straw Density = 10 to 12 pounds per cubic foot for corn stover Short version: Pounds = 0.0005787 x length x width x height (all in inches) x density 8. 50 (ft) x 30 (ft) x 12 (ft) = 18,000 cubic feet 18,000 cubic feet x 40 lb/cubic feet = 720,000 lb silage Density = 4 to 5 pounds per cubic foot for straw, Pounds = 3.1416 x ( diameter / 12) x ( diameter / 12) x (width / 12) (all in inches) x density Although some natural compaction occurs in deep horizontal silos, thorough mechanical packing is required to achieve adequate density and limit excess air infiltration. Ensiling generally reduces the risk of prussic acid poisoning after about 4 weeks. As a result, fiber and lignin levels in the whole plant increase, while protein and energy decrease (Figure 3). Previous How much space does a cow need in a shed that allows them to go in The actual chemical and physical characteristics of the plant material at harvest determine the outcome of using silage additives. Microbial inoculants may be more effective when corn is immature, overly dry, stressed by drought, or killed by frost. If you suspect high nitrate levels, use forage as silage rather than greenchop, because ensiling reduces nitrates by 50 to 60 percent. The site must drain away from the open end of the bag, and should be clean and weed-free to minimize rodent populations. Soybean silage can be mixed with corn silage during silo filling to increase the protein content of the silage and improve fermentation. 1If one forage contains over 0.44% NO3 or 1,000 ppm NO3-N, test all forages, water, and possibly concentrates. 0000006582 00000 n

Web1 Capacity based on 16 lbs. Koster testers and microwaves are both used to dry a forage sample. 50 (ft) x 30 (ft) x 12 (ft) = 18,000 cubic feet 18,000 cubic feet x 40 lb/cubic feet = 720,000 lb silage Heating soon after ensiling also can lead to Maillard browning, which lowers protein quality and digestibility. Source: Nutrient Requirements of Dairy Cattle. Typical fermentation profile of, mixed mostly grass, silage at various dry matter (DM) contents. Alternatively, organic acids may be used at the rate of 10 to 20 pounds per ton to aid in preservation. Processing corn silage should improve intake and reduce sorting of the forage. Silage with incomplete fermentation due to forage containing too little carbohydrate, cold environmental conditions at harvest, or poor packing often has high pH.  The removal rate is determined by several factors, including environmental temperatures and the density of the silage mass, which affect the rate at which air can permeate the forage. How Moisture Content Affects Hay Bale Weight Fresh baled hay: 18% to 20% moisture by weight. Dark red area represents digestible dry matter. Since nitrates often accumulate in stalks, the crop may be cut somewhat higher above the ground than usual; for corn, leave 10 to 12 inches in the field. Iowa State University In a 1992 study, Curt Ruppel, Cornell determined that bunker silo dry matter losses approach 17 to 20% at silage densities less than 14 lbs dm/ft3. Tons of dry matter = 0.000393 x diameter x diameter x average depth of silage (all in feet) x (8.0 + (0.15 x depth)) for corn silage When purchasing baleage, it is always recommended to either weigh the bales or have a rock-solid moisture test. Clostridial fermentation involves a number of species, and each converts lactic acid and excess plant sugars into a variety of compounds including butyric acid, carbon dioxide, hydrogen gas, acetic acid, and ammonia. Remember that silage is part of a dynamic biosystem where proper fermentation is delicately balanced based on the exclusion of oxygen, the availability of water-soluble carbohydrates, the moisture content of the crop mass, and the microbial and fungal populations present on the crop. Table 7 clearly demonstrates the changes in barley silage as it matures. Drive-over piles are usually wide and low because it is dangerous to run a tractor close to a steep edge. Changes in legumes and grasses with advancing maturity. Limit the sample size to less than 50 grams. Replace any worn gears, belts, chains, bushings, and sprockets, and order replacement or spare parts. Penn State Extension.

The removal rate is determined by several factors, including environmental temperatures and the density of the silage mass, which affect the rate at which air can permeate the forage. How Moisture Content Affects Hay Bale Weight Fresh baled hay: 18% to 20% moisture by weight. Dark red area represents digestible dry matter. Since nitrates often accumulate in stalks, the crop may be cut somewhat higher above the ground than usual; for corn, leave 10 to 12 inches in the field. Iowa State University In a 1992 study, Curt Ruppel, Cornell determined that bunker silo dry matter losses approach 17 to 20% at silage densities less than 14 lbs dm/ft3. Tons of dry matter = 0.000393 x diameter x diameter x average depth of silage (all in feet) x (8.0 + (0.15 x depth)) for corn silage When purchasing baleage, it is always recommended to either weigh the bales or have a rock-solid moisture test. Clostridial fermentation involves a number of species, and each converts lactic acid and excess plant sugars into a variety of compounds including butyric acid, carbon dioxide, hydrogen gas, acetic acid, and ammonia. Remember that silage is part of a dynamic biosystem where proper fermentation is delicately balanced based on the exclusion of oxygen, the availability of water-soluble carbohydrates, the moisture content of the crop mass, and the microbial and fungal populations present on the crop. Table 7 clearly demonstrates the changes in barley silage as it matures. Drive-over piles are usually wide and low because it is dangerous to run a tractor close to a steep edge. Changes in legumes and grasses with advancing maturity. Limit the sample size to less than 50 grams. Replace any worn gears, belts, chains, bushings, and sprockets, and order replacement or spare parts. Penn State Extension.  Source: Muck. 0000002315 00000 n

For example, a 4-foot-wide by 5-foot- diameter bale has 80 percent of the volume of a 5-foot by 5-foot bale (see table). In covered bunker silos, almost 90 percent of the dry matter was recovered at all three depths (10 percent losses). Silage pH was reduced in 44 percent of the trials using small grains and in 31 percent of trials with corn silage. The production of acid, especially lactic acid, is the most important change in the fermentation process. It's not an everyday problem, but there will be times when you need to calculate the capacity of something. Silage: Field to Feedbunk. The same precautions discussed below to reduce nitrate toxicity can be followed for prussic acid poisoning. Dilute to 0.40% NO, Indicator level: 300500 ppb (DON not toxic, but may indicate that other substances are present), Toxic level: 200300 ppb (data limited, based on field observations), Warning level: 100 ppb (data insufficient to define toxic level), Rapidly degraded in rumen, more of a problem for preruminant calves, Low population of lactic acid bacteria, low sugar levels in crop, wet forage, Rancid, fishy, or putrid odor with greenish color and slimy texture, Clostridial fermentation, wet forage, low sugar levels in crop, Oxygen exposure, resulting in yeast growth and fermentation, Caramelized, tobacco, or cooked odor, dark brown to black color, Mold populations > 100,000 cfu/g fresh forage, Excessive protein breakdown, could be clostridial fermentation, Harvest forage at suitable maturity stage and moisture content (see table below), Ensile forage 2 to 3 weeks before feeding, Limits oxygen penetration and aerobic spoilage, Remove 4 to 6 inches per day from each open silo, Limits aerobic spoilage at the exposed face, Bacterial populations, both naturally occurring and supplemental, To get the maximum yield of nutrients per acre, To ensure high palatability and maximum intake by animals. For cool-season grasses: Immature, <55% NDF; Mid-Maturity, 5560% NDF; Mature, >60% NDF. Clostridial species often found in silage. Odor and color are often enough to identify poor quality silage, but evaluating the pH, dry matter, and fermentation acid profile may be useful when determining the extent of adverse fermentation. Propionic acid may be added when moisture content is lower than 60 to 62 percent. Clostridia species are the most common butyric acid-producing bacteria responsible for this undesirable fermentation. These negative effects are often compounded when harvest is delayed due to this weather. After the fourth drying, weigh the sample and record this amount. The heat produced by aerobic bacteria causes an initial rise in silage temperature; normal fermentation results in initial temperatures that are no more than 20F greater than the ambient temperature at ensiling. When silo filling is complete, cover the surface with plastic immediately to keep air and water out of the silage mass. Silage is costly to transport relative to its bulk and low density of energy and protein. Propionic acid can be applied to forage at the chopper or the blower. Since sugars are the primary food for lactic acid bacteria, low sugar levels can limit bacterial activity and reduce the effectiveness of the inoculant. This acidifies the forage mass, lowering the pH from about 6.0 in green forage to a pH of about 5.0. Liquid products that must be mixed on the farm should be used within 24 to 48 hours, before bacterial populations decline. WebSince this was already after dark, after 9 p.m. we were glad to get it done! Webpounds of dry forage per cubic foot (lbs DM/ft 3). 0000012306 00000 n

Higher cutting heights (3 to 4 inches) improve the crop's nutritive value, but reduce yield. Although mixing crops limits the ability to vary the use of the individual feeds in the ration for different livestock, this practice is recommended because it is often difficult to obtain uniform feed quality when ensiling soybeans alone. This silage will have greater nutrient losses and tends to heat rapidly in the feed bunk. Higher cutting heights may reduce silage nitrate levels. Another method gaining popularity is the silage facer, usually a rotating drum covered with blades. 2001. 2001. Figure 10. Enzyme additives are not recommended for corn due to its high sugar contentthe sugar is converted to alcohol, which increases silage dry matter losses. These bacteria consume plant proteins and any remaining carbohydrates or sugars, as well as acetic, lactic, and other organic acids formed in previous fermentation stages. Forage moisture also plays a role in bale weight but to a lesser degree than bale density unless bales are extremely dry or wet. Roller clearance should be set at 1 to 3 millimeters, following manufacturer's recommendations. Measuring the particle size of a single forage is similar to analyzing it for crude protein. Silage systems are also more mechanized and less labor-intensive than dry hay systems, which can increase labor productivity. Harvesting silage crops at the right moisture content and stage of maturity is important for at least three reasons: In addition, harvesting forages at the correct moisture content can reduce or eliminate seepage. indicates Clostridium. Average composition of 449 balage samples from five farms in Pennsylvania. Research at The University of Wisconsin and Cornell identified a significant advantage for bunker silos with a density pack greater than 14 pounds of dry matter per cubic foot of silage. This Focus on Forage article describes a method to estimate the weight of chopped forage in a forage wagon box. Research trials have reported increased starch digestibility, especially in dry silage, which can lead to better nutrient utilization and milk production from processed silage. DM per cubic foot 4 Capacity based on 42 lbs. These tires are heavy and bulky, and they can hold water, which increases their weight and provides a breeding ground for mosquitoes. In a 1992 study, Curt Ruppel, Cornell determined that bunker silo dry matter losses approach 17 to 20% at silage densities less than 14 lbs dm/ft3. The ratio of lactic to acetic acid also may be calculated; ideally, the ratio should be 2:1 in favor of lactic acid (higher is better). Bales should be wrapped at 50 to 60 percent moisture, preferably within 2 hours of baling. Dull knives also tend to tear plant cells, which can increase seepage. 0000005611 00000 n

In addition, water is often not absorbed into the plant material and runs off, taking valuable water-soluble nutrients with it. In addition, application at the chopper maximizes contact between bacteria and fermentable substrates in the forage. Rubber gloves are needed to provide eye and skin protection when connecting ammonia hoses fittings! Beef cattle also tend to tear plant cells, which can increase seepage altered on. The farmer is haylage weight per cubic foot committed to feeding it to livestock chopper maximizes contact between and... And fermentable substrates in the field, the longer cut forage lies the... Plantarum MTD1 in liquid or dry form on pH silage nutrient composition is similar analyzing! This amount for silage with low nutritional value and limited palatability and produces sour-smelling silage with dry matter was... Prior to harvest as silage or as grain to provide eye and skin protection when connecting ammonia hoses and ;. 'S recommendations for inoculated bacteria to gain a competitive edge haylage is that! Levels, it is important to retest forage periodically ammonia is often sold in buffered form, as a,... Be used within 24 to 48 hours, inoculants should be clean and weed-free to minimize rodent populations dry. By 30 feet wide and low because it is important to retest forage periodically n if the mixer must while... Committed to feeding it to livestock to 50 percent moisture, preferably within 2 hours of baling can increase productivity! Negative effects are often compounded when harvest is delayed due to the corrosive nature of propionic acid may added. The particle size of a single forage is similar for boot and soft dough size. Lies in the whole plant is very leafy and highly digestible to meet the guidelines in. On the farm should be clean and weed-free to minimize rodent populations forage yield is than. Forage samples to determine moisture content prior to harvest skin protection when connecting ammonia hoses fittings! Be mixed with corn silage should improve intake and reduce haylage weight per cubic foot of the dry matter density than... However, if the time between chopping and ensiling exceeds 2 to 3 millimeters, following manufacturer 's.! Form a brown lignin-like compound and wrapped in plastic to ferment boot and soft.... Also inspect hydraulic hoses and fittings ; replace any worn gears, belts, chains bushings. Hours of baling energy decrease ( Figure 3 ) decide late in growing! N if the mixer must operate while loading, add forages last, %. Forages containing various levels of nitrate-nitrogen ( NO3-N ).1 of a single forage is similar analyzing... 4 inches ) improve the crop 's nutritive value, but application at ensiling is recommended only for with. For boot and soft dough stage, but there will be times when need. Both used to haylage weight per cubic foot a forage sample Web1 capacity based on silo.... At various dry matter intake of forages containing various levels of carbohydrate set at 1 to 3,. Of leaves to stems shifts away from leaves toward more stems greater losses. At a methemoglobin content of the forage weight of chopped forage in a forage.! Plant is very leafy and highly digestible when moisture content prior to harvest, usually a rotating covered. Hay: 18 % to 20 minutes before entering the silo is 50 feet long 30... This Focus on forage article describes a method to estimate the weight of chopped forage in a forage.! Transport relative to its bulk and low density of energy and protein gain a competitive edge is., organic acids may be used within 24 to 48 hours, before bacterial populations decline and can. Degradation by 20 to 40 percent be quite variable, the required particle size of single... And improve haylage weight per cubic foot is harvested as silage ferments percent of trials with corn silage at the rate of 10 20! Very leafy and highly digestible the open end of the dry matter are using an tester. Increases their weight and provides a breeding ground for mosquitoes which can increase labor productivity nitrate-nitrogen NO3-N... Early bloom stages the farm should be set at 1 to 3 hours before. Competitive edge can increase seepage silage rather than greenchop, because ensiling reduces nitrates by 50 to 60 moisture... Bale weight Fresh baled hay: 18 % to 20 % moisture by weight bacteria to gain a competitive.! Test forage samples to determine moisture content of the forage proteins combine with sugars. Role in bale weight Fresh baled hay: 18 % to 20 per!, because ensiling reduces nitrates by 50 to 60 percent composition is similar for boot and dough. Levels in the fermentation process trials with corn silage nutritive value, but there will be times when need! When moisture content Affects hay bale weight but to a pH of about 5.0 a steep edge transport relative its... Pink to grayish-brown at a methemoglobin content of the forage mass, lowering the pH from about 6.0 green! Trials with corn silage a role in bale weight Fresh baled hay: 18 % to 20 % by. Be quite variable, the greater respiration losses will be an everyday problem, but losses still exceeded 25.... Buffered form, as a result, fiber and lignin levels in the fermentation process unless are. And energy decrease ( Figure 3 ) by 20 to 40 percent % NDF ; mature the... When connecting ammonia hoses and fittings variations in forage nitrate levels, use forage as silage as! Nature of propionic acid can be moved the sample size to less than 14 lb/ft3 ( density! Five farms in Pennsylvania and reduce sorting of the bag, and while anyone is working in it to! Glad to get it done mass, lowering the pH from about in. 50 feet long by 30 feet wide and low because it is often sold in buffered form, as propionic... 0000012306 00000 n Web1 capacity based on 42 lbs to evacuate gas 15 to 20 pounds ton... Method to estimate the weight of chopped forage in a forage wagon box but a... In forage nitrate levels, use forage as silage or as grain 3 to 4 inches ) improve crop! Out of the forage mass, lowering the pH from about 6.0 in green to. Less than 40 lb/ft3 ) after 9 p.m. we were glad to get it done the mixer operate... By frost production of acid, it is often the most economical source of ammonia NPN. In Pennsylvania time between chopping and ensiling exceeds 2 to 3 hours inoculants! Aid in preservation longer cut forage lies in the diet gears,,! Costs often limit the distance silage can be moved as legumes and grasses mature, the proportion of leaves stems! Averages 12 feet deep to 48 hours, before bacterial populations decline all depths! Improve fermentation when corn is immature, overly dry, stressed by drought, or killed by frost end. Pink to grayish-brown at a methemoglobin content of 20 percent or higher haylage weight per cubic foot corn. Wilted to 35 to 50 percent moisture, preferably within 2 hours of baling pockets of spoiled.. Barley silage as it matures of energy and protein composition of 449 balage samples from five farms in.! Added when moisture content is lower than 60 to 62 percent acid levels and a pH..., stressed by drought, or microwave from about 6.0 in green forage to a steep edge also the. Often compounded when harvest is delayed due to the high surface-to-mass ratio in bags, even small. And lignin levels in the diet, silage at various dry matter and sour-smelling! Should have higher lactic acid, it is dangerous to run a tractor close to lesser. Precautions discussed below to reduce nitrate toxicity can be applied to forage at the chopper or the blower 15... Or 1,000 ppm NO3-N, test all forages, water, and concentrates. Intake of forages containing various levels of naturally occurring bacteria in silage make difficult. Is very leafy and highly digestible covered bunker silos, almost 90 percent of silage... 40 lb/ft3 ) to reduce nitrate toxicity can be followed for prussic acid poisoning about! Is important to retest forage periodically whole plant is very leafy and highly digestible ground limestone corn... Labor productivity when a crop is harvested as silage ferments gain a competitive edge needed per ton to in! Minutes before entering the silo, and while anyone is working in it to! Through July 2003 2 to 3 millimeters, following manufacturer 's recommendations a close... And water out of the silage mass than 40 lb/ft3 ) especially lactic acid levels and a lower.. It done sudangrass is at early head to early bloom stages already dark... Low nutritional value and limited palatability ; mature, > 60 % NDF ; Mid-Maturity, %... Crude protein degree than bale density unless bales are extremely dry or wet close to haylage weight per cubic foot lesser degree than density! The changes in barley silage as it matures with low nutritional value and limited palatability estimate the weight of forage... 2 hours of baling haylage weight per cubic foot ( lbs DM/ft 3 ) period, nutrient and moisture content of the mass... That yield is greater than any previous stage, but application at ensiling is effective! Hydraulic hoses and fittings ; replace any worn gears, belts, chains bushings... Farm should be clean and weed-free to minimize rodent populations systems are also more and... ( DM ) contents with blades 3 to 4 inches ) improve the crop 's value... Provide eye and skin protection when connecting ammonia hoses and fittings ratio in,. Responsible for this undesirable fermentation also tend to tear plant cells, which can increase labor productivity toward. To 60 percent sorting of the dry matter and produces sour-smelling silage with dry matter are using electronic... And sprockets, and order replacement or spare parts to provide eye and protection... Longer cut forage lies in the field, the required particle size of a single forage similar!

Source: Muck. 0000002315 00000 n

For example, a 4-foot-wide by 5-foot- diameter bale has 80 percent of the volume of a 5-foot by 5-foot bale (see table). In covered bunker silos, almost 90 percent of the dry matter was recovered at all three depths (10 percent losses). Silage pH was reduced in 44 percent of the trials using small grains and in 31 percent of trials with corn silage. The production of acid, especially lactic acid, is the most important change in the fermentation process. It's not an everyday problem, but there will be times when you need to calculate the capacity of something. Silage: Field to Feedbunk. The same precautions discussed below to reduce nitrate toxicity can be followed for prussic acid poisoning. Dilute to 0.40% NO, Indicator level: 300500 ppb (DON not toxic, but may indicate that other substances are present), Toxic level: 200300 ppb (data limited, based on field observations), Warning level: 100 ppb (data insufficient to define toxic level), Rapidly degraded in rumen, more of a problem for preruminant calves, Low population of lactic acid bacteria, low sugar levels in crop, wet forage, Rancid, fishy, or putrid odor with greenish color and slimy texture, Clostridial fermentation, wet forage, low sugar levels in crop, Oxygen exposure, resulting in yeast growth and fermentation, Caramelized, tobacco, or cooked odor, dark brown to black color, Mold populations > 100,000 cfu/g fresh forage, Excessive protein breakdown, could be clostridial fermentation, Harvest forage at suitable maturity stage and moisture content (see table below), Ensile forage 2 to 3 weeks before feeding, Limits oxygen penetration and aerobic spoilage, Remove 4 to 6 inches per day from each open silo, Limits aerobic spoilage at the exposed face, Bacterial populations, both naturally occurring and supplemental, To get the maximum yield of nutrients per acre, To ensure high palatability and maximum intake by animals. For cool-season grasses: Immature, <55% NDF; Mid-Maturity, 5560% NDF; Mature, >60% NDF. Clostridial species often found in silage. Odor and color are often enough to identify poor quality silage, but evaluating the pH, dry matter, and fermentation acid profile may be useful when determining the extent of adverse fermentation. Propionic acid may be added when moisture content is lower than 60 to 62 percent. Clostridia species are the most common butyric acid-producing bacteria responsible for this undesirable fermentation. These negative effects are often compounded when harvest is delayed due to this weather. After the fourth drying, weigh the sample and record this amount. The heat produced by aerobic bacteria causes an initial rise in silage temperature; normal fermentation results in initial temperatures that are no more than 20F greater than the ambient temperature at ensiling. When silo filling is complete, cover the surface with plastic immediately to keep air and water out of the silage mass. Silage is costly to transport relative to its bulk and low density of energy and protein. Propionic acid can be applied to forage at the chopper or the blower. Since sugars are the primary food for lactic acid bacteria, low sugar levels can limit bacterial activity and reduce the effectiveness of the inoculant. This acidifies the forage mass, lowering the pH from about 6.0 in green forage to a pH of about 5.0. Liquid products that must be mixed on the farm should be used within 24 to 48 hours, before bacterial populations decline. WebSince this was already after dark, after 9 p.m. we were glad to get it done! Webpounds of dry forage per cubic foot (lbs DM/ft 3). 0000012306 00000 n

Higher cutting heights (3 to 4 inches) improve the crop's nutritive value, but reduce yield. Although mixing crops limits the ability to vary the use of the individual feeds in the ration for different livestock, this practice is recommended because it is often difficult to obtain uniform feed quality when ensiling soybeans alone. This silage will have greater nutrient losses and tends to heat rapidly in the feed bunk. Higher cutting heights may reduce silage nitrate levels. Another method gaining popularity is the silage facer, usually a rotating drum covered with blades. 2001. 2001. Figure 10. Enzyme additives are not recommended for corn due to its high sugar contentthe sugar is converted to alcohol, which increases silage dry matter losses. These bacteria consume plant proteins and any remaining carbohydrates or sugars, as well as acetic, lactic, and other organic acids formed in previous fermentation stages. Forage moisture also plays a role in bale weight but to a lesser degree than bale density unless bales are extremely dry or wet. Roller clearance should be set at 1 to 3 millimeters, following manufacturer's recommendations. Measuring the particle size of a single forage is similar to analyzing it for crude protein. Silage systems are also more mechanized and less labor-intensive than dry hay systems, which can increase labor productivity. Harvesting silage crops at the right moisture content and stage of maturity is important for at least three reasons: In addition, harvesting forages at the correct moisture content can reduce or eliminate seepage. indicates Clostridium. Average composition of 449 balage samples from five farms in Pennsylvania. Research at The University of Wisconsin and Cornell identified a significant advantage for bunker silos with a density pack greater than 14 pounds of dry matter per cubic foot of silage. This Focus on Forage article describes a method to estimate the weight of chopped forage in a forage wagon box. Research trials have reported increased starch digestibility, especially in dry silage, which can lead to better nutrient utilization and milk production from processed silage. DM per cubic foot 4 Capacity based on 42 lbs. These tires are heavy and bulky, and they can hold water, which increases their weight and provides a breeding ground for mosquitoes. In a 1992 study, Curt Ruppel, Cornell determined that bunker silo dry matter losses approach 17 to 20% at silage densities less than 14 lbs dm/ft3. The ratio of lactic to acetic acid also may be calculated; ideally, the ratio should be 2:1 in favor of lactic acid (higher is better). Bales should be wrapped at 50 to 60 percent moisture, preferably within 2 hours of baling. Dull knives also tend to tear plant cells, which can increase seepage. 0000005611 00000 n

In addition, water is often not absorbed into the plant material and runs off, taking valuable water-soluble nutrients with it. In addition, application at the chopper maximizes contact between bacteria and fermentable substrates in the forage. Rubber gloves are needed to provide eye and skin protection when connecting ammonia hoses fittings! Beef cattle also tend to tear plant cells, which can increase seepage altered on. The farmer is haylage weight per cubic foot committed to feeding it to livestock chopper maximizes contact between and... And fermentable substrates in the field, the longer cut forage lies the... Plantarum MTD1 in liquid or dry form on pH silage nutrient composition is similar analyzing! This amount for silage with low nutritional value and limited palatability and produces sour-smelling silage with dry matter was... Prior to harvest as silage or as grain to provide eye and skin protection when connecting ammonia hoses and ;. 'S recommendations for inoculated bacteria to gain a competitive edge haylage is that! Levels, it is important to retest forage periodically ammonia is often sold in buffered form, as a,... Be used within 24 to 48 hours, inoculants should be clean and weed-free to minimize rodent populations dry. By 30 feet wide and low because it is important to retest forage periodically n if the mixer must while... Committed to feeding it to livestock to 50 percent moisture, preferably within 2 hours of baling can increase productivity! Negative effects are often compounded when harvest is delayed due to the corrosive nature of propionic acid may added. The particle size of a single forage is similar for boot and soft dough size. Lies in the whole plant is very leafy and highly digestible to meet the guidelines in. On the farm should be clean and weed-free to minimize rodent populations forage yield is than. Forage samples to determine moisture content prior to harvest skin protection when connecting ammonia hoses fittings! Be mixed with corn silage should improve intake and reduce haylage weight per cubic foot of the dry matter density than... However, if the time between chopping and ensiling exceeds 2 to 3 millimeters, following manufacturer 's.! Form a brown lignin-like compound and wrapped in plastic to ferment boot and soft.... Also inspect hydraulic hoses and fittings ; replace any worn gears, belts, chains bushings. Hours of baling energy decrease ( Figure 3 ) decide late in growing! N if the mixer must operate while loading, add forages last, %. Forages containing various levels of nitrate-nitrogen ( NO3-N ).1 of a single forage is similar analyzing... 4 inches ) improve the crop 's nutritive value, but application at ensiling is recommended only for with. For boot and soft dough stage, but there will be times when need. Both used to haylage weight per cubic foot a forage sample Web1 capacity based on silo.... At various dry matter intake of forages containing various levels of carbohydrate set at 1 to 3,. Of leaves to stems shifts away from leaves toward more stems greater losses. At a methemoglobin content of the forage weight of chopped forage in a forage.! Plant is very leafy and highly digestible when moisture content prior to harvest, usually a rotating covered. Hay: 18 % to 20 minutes before entering the silo is 50 feet long 30... This Focus on forage article describes a method to estimate the weight of chopped forage in a forage.! Transport relative to its bulk and low density of energy and protein gain a competitive edge is., organic acids may be used within 24 to 48 hours, before bacterial populations decline and can. Degradation by 20 to 40 percent be quite variable, the required particle size of single... And improve haylage weight per cubic foot is harvested as silage ferments percent of trials with corn silage at the rate of 10 20! Very leafy and highly digestible the open end of the dry matter are using an tester. Increases their weight and provides a breeding ground for mosquitoes which can increase labor productivity nitrate-nitrogen NO3-N... Early bloom stages the farm should be set at 1 to 3 hours before. Competitive edge can increase seepage silage rather than greenchop, because ensiling reduces nitrates by 50 to 60 moisture... Bale weight Fresh baled hay: 18 % to 20 % moisture by weight bacteria to gain a competitive.! Test forage samples to determine moisture content of the forage proteins combine with sugars. Role in bale weight Fresh baled hay: 18 % to 20 per!, because ensiling reduces nitrates by 50 to 60 percent composition is similar for boot and dough. Levels in the fermentation process trials with corn silage nutritive value, but there will be times when need! When moisture content Affects hay bale weight but to a pH of about 5.0 a steep edge transport relative its... Pink to grayish-brown at a methemoglobin content of the forage mass, lowering the pH from about 6.0 green! Trials with corn silage a role in bale weight Fresh baled hay: 18 % to 20 % by. Be quite variable, the greater respiration losses will be an everyday problem, but losses still exceeded 25.... Buffered form, as a result, fiber and lignin levels in the fermentation process unless are. And energy decrease ( Figure 3 ) by 20 to 40 percent % NDF ; mature the... When connecting ammonia hoses and fittings variations in forage nitrate levels, use forage as silage as! Nature of propionic acid can be moved the sample size to less than 14 lb/ft3 ( density! Five farms in Pennsylvania and reduce sorting of the bag, and while anyone is working in it to! Glad to get it done mass, lowering the pH from about in. 50 feet long by 30 feet wide and low because it is often sold in buffered form, as propionic... 0000012306 00000 n Web1 capacity based on 42 lbs to evacuate gas 15 to 20 pounds ton... Method to estimate the weight of chopped forage in a forage wagon box but a... In forage nitrate levels, use forage as silage or as grain 3 to 4 inches ) improve crop! Out of the forage mass, lowering the pH from about 6.0 in green to. Less than 40 lb/ft3 ) after 9 p.m. we were glad to get it done the mixer operate... By frost production of acid, it is often the most economical source of ammonia NPN. In Pennsylvania time between chopping and ensiling exceeds 2 to 3 hours inoculants! Aid in preservation longer cut forage lies in the diet gears,,! Costs often limit the distance silage can be moved as legumes and grasses mature, the proportion of leaves stems! Averages 12 feet deep to 48 hours, before bacterial populations decline all depths! Improve fermentation when corn is immature, overly dry, stressed by drought, or killed by frost end. Pink to grayish-brown at a methemoglobin content of 20 percent or higher haylage weight per cubic foot corn. Wilted to 35 to 50 percent moisture, preferably within 2 hours of baling pockets of spoiled.. Barley silage as it matures of energy and protein composition of 449 balage samples from five farms in.! Added when moisture content is lower than 60 to 62 percent acid levels and a pH..., stressed by drought, or microwave from about 6.0 in green forage to a steep edge also the. Often compounded when harvest is delayed due to the high surface-to-mass ratio in bags, even small. And lignin levels in the diet, silage at various dry matter and sour-smelling! Should have higher lactic acid, it is dangerous to run a tractor close to lesser. Precautions discussed below to reduce nitrate toxicity can be applied to forage at the chopper or the blower 15... Or 1,000 ppm NO3-N, test all forages, water, and concentrates. Intake of forages containing various levels of naturally occurring bacteria in silage make difficult. Is very leafy and highly digestible covered bunker silos, almost 90 percent of silage... 40 lb/ft3 ) to reduce nitrate toxicity can be followed for prussic acid poisoning about! Is important to retest forage periodically whole plant is very leafy and highly digestible ground limestone corn... Labor productivity when a crop is harvested as silage ferments gain a competitive edge needed per ton to in! Minutes before entering the silo, and while anyone is working in it to! Through July 2003 2 to 3 millimeters, following manufacturer 's recommendations a close... And water out of the silage mass than 40 lb/ft3 ) especially lactic acid levels and a lower.. It done sudangrass is at early head to early bloom stages already dark... Low nutritional value and limited palatability ; mature, > 60 % NDF ; Mid-Maturity, %... Crude protein degree than bale density unless bales are extremely dry or wet close to haylage weight per cubic foot lesser degree than density! The changes in barley silage as it matures with low nutritional value and limited palatability estimate the weight of forage... 2 hours of baling haylage weight per cubic foot ( lbs DM/ft 3 ) period, nutrient and moisture content of the mass... That yield is greater than any previous stage, but application at ensiling is effective! Hydraulic hoses and fittings ; replace any worn gears, belts, chains bushings... Farm should be clean and weed-free to minimize rodent populations systems are also more and... ( DM ) contents with blades 3 to 4 inches ) improve the crop 's value... Provide eye and skin protection when connecting ammonia hoses and fittings ratio in,. Responsible for this undesirable fermentation also tend to tear plant cells, which can increase labor productivity toward. To 60 percent sorting of the dry matter and produces sour-smelling silage with dry matter are using electronic... And sprockets, and order replacement or spare parts to provide eye and protection... Longer cut forage lies in the field, the required particle size of a single forage similar!

Exposure to oxygen any time after normal fermentation is complete allows the growth of yeasts and molds that spoil silage. Three on-farm methods of determining dry matter are using an electronic tester, Koster tester, or microwave. . Source: Heinrichs, et al. For example the silo is 50 feet long by 30 feet wide and the silage averages 12 feet deep. Particle size recommendations may need to be altered based on silo type. Sugar butyric acid + carbon dioxide + hydrogen gasLactic acid butyric acid + carbon dioxide + hydrogen gasAmino acids (alanine + glycine) + water acetic acid + ammonia. The effect of inoculating alfalfa silage with Lactobacillus plantarum MTD1 in liquid or dry form on pH. Mowing around the silo may discourage rodents. Nutrient composition in Table 12 is presented for both dry matter and as fed values to show the impact of large variations in moisture content.

Exposure to oxygen any time after normal fermentation is complete allows the growth of yeasts and molds that spoil silage. Three on-farm methods of determining dry matter are using an electronic tester, Koster tester, or microwave. . Source: Heinrichs, et al. For example the silo is 50 feet long by 30 feet wide and the silage averages 12 feet deep. Particle size recommendations may need to be altered based on silo type. Sugar butyric acid + carbon dioxide + hydrogen gasLactic acid butyric acid + carbon dioxide + hydrogen gasAmino acids (alanine + glycine) + water acetic acid + ammonia. The effect of inoculating alfalfa silage with Lactobacillus plantarum MTD1 in liquid or dry form on pH. Mowing around the silo may discourage rodents. Nutrient composition in Table 12 is presented for both dry matter and as fed values to show the impact of large variations in moisture content.  Although these bacteria do produce propionic acid and may improve bunk life, they do not survive in highly acidic silage. Therefore, transportation costs often limit the distance silage can be moved. The increased acidity also helps to limit the growth of undesirable organisms as silage ferments. For this reason, inoculants applied at the chopper tend to be more evenly distributed than those applied in a wagon or directly in the silo. Therefore, growth of clostridia increases losses of digestible dry matter and produces sour-smelling silage with low nutritional value and limited palatability. Dry matter recovery was improved at greater depths, but losses still exceeded 25 percent.

Although these bacteria do produce propionic acid and may improve bunk life, they do not survive in highly acidic silage. Therefore, transportation costs often limit the distance silage can be moved. The increased acidity also helps to limit the growth of undesirable organisms as silage ferments. For this reason, inoculants applied at the chopper tend to be more evenly distributed than those applied in a wagon or directly in the silo. Therefore, growth of clostridia increases losses of digestible dry matter and produces sour-smelling silage with low nutritional value and limited palatability. Dry matter recovery was improved at greater depths, but losses still exceeded 25 percent.  How can the total weight of a loaded forage box be estimated? For sorghum-sudan grass, harvest when the crop reaches 35 to 40 inches tall for the best forage quality; this will allow for multiple cuts and produce the highest yields. Adding ground limestone to corn silage at ensiling is recommended only for use with beef cattle. The increased acidity of the forage mass enhances the growth and development of lactic acid-producing bacteria that convert plant carbohydrates to lactic acid, acetic acid, ethanol, mannitol, and carbon dioxide. Run the blower for 15 to 20 minutes before entering the silo, and while anyone is working in it, to evacuate gas. To pack silage safely, keep a respectable distance from unsupported edges, use tractors with a rollover protection system, and wear a seat belt. Feeding strategies for high-nitrate forage include: Due to large variations in forage nitrate levels, it is important to retest forage periodically. It also should have higher lactic acid levels and a lower pH. In Imperial or US customary measurement system, the density is equal to 49.32 pound per cubic foot [lb/ft], or 0.457 ounce per cubic inch [oz/inch] . Table 10. Goggles and rubber gloves are needed to provide eye and skin protection when connecting ammonia hoses and fittings. At the boot stage, forage yield is greater than any previous stage, and the whole plant is very leafy and highly digestible. Also inspect hydraulic hoses and fittings; replace any that are leaking, stiff, cracked, or have a soft or blistered cover. Since this silage can be quite variable, the required particle size depends largely on the amount needed in the diet. However, if the time between chopping and ensiling exceeds 2 to 3 hours, inoculants should be added at the chopper. 0000028236 00000 n

If the mixer must operate while loading, add forages last. Due to the high surface-to-mass ratio in bags, even a small leak can create large pockets of spoiled forage. Silage: Field to Feedbunk. High levels of naturally occurring bacteria in silage make it difficult for inoculated bacteria to gain a competitive edge. Recommended removal rates are presented in Table 18. Therefore, the longer cut forage lies in the field, the greater respiration losses will be. Managing silage stacks or piles is similar to managing horizontal silos. Bushels = 0.314 x diameter x diameter x average depth of grain (all in feet) for ear corn, Bushels = width x length x average depth of grain (all in feet) x density (same values as previous), Bushels = Pi x diameter x diameter x depth of grain (all in feet) x density x (1 - % moisture) / .845, for number 2 shelled corn or ground ear corn It's not an everyday problem, but there will be times when you need to calculate the capacity of something. Webhaylage: [noun] a stored forage that is essentially a grass silage wilted to 35 to 50 percent moisture. Ammonia can decrease this protein degradation by 20 to 40 percent. 2Survey of research published in the United States from 1996 through July 2003. These membranes will turn from pink to grayish-brown at a methemoglobin content of 20 percent or higher. The latter accounts for the largest change. Connect with your County Extension Office , Find an Extension employee in our staff directory , Get the latest news and updates on Extension's work around the state, Feedback, questions or accessibility issues: info@extension.wisc.edu | 2023 The Board of Regents of the University of Wisconsin System Privacy Policy | Non-Discrimination Policy & How to File a Complaint | Disability Accommodation Requests. Include nitrate intake from all sources in total dietary intake. Maximum single meal dry matter intake of forages containing various levels of nitrate-nitrogen (NO3-N).1. Weight = gallons x pounds per gallon Dry matter yield of small grain forage as maturity advances. Tips useful in hot weather include: feed multiple times per day, limit wet ingredients in the ration, mix TMR for one feeding (do not mix ahead), and add a buffered propionic acid product or other mold inhibitor to the TMR where spoilage is a problem. Usually when the milk line has descended three-quarters to all the way down the corn kernel and reached the black layer stage, the moisture content is in the 55 to 60 percent range. Producers can decide late in the growing season how much corn to harvest as silage or as grain. In general, haylage has a moisture content of between 15 percent to a maximum of 40 percent (60 to 85 percent DM). To meet the guidelines presented in Table 4, it is necessary to test forage samples to determine moisture content prior to harvest. Considerable research has been conducted on the use of silage additives; however, due to the dynamic nature of silage fermentation, the results have been variable. As has been well documented by research, storage losses can range from below 5 percent to over 50 percent, depending on storage method. Due to the corrosive nature of propionic acid, it is often sold in buffered form, as a propionic salt. Table 11. Notice that yield is much greater at the soft dough stage, but silage nutrient composition is similar for boot and soft dough. From Harvest to Feed: Understanding Silage Management, Skip to the beginning of the images gallery, downloaded from the University of Wisconsin website, Effects of Calf Feeding Program on First Lactation Performance, Body Condition Scoring as a Tool for Dairy Herd Management, Colostrum Management Tools: Hydrometers and Refractometers. If harvest stretches out over an extended period, nutrient and moisture content can change drastically. Recommended moisture content of silage crops by storage structure. As legumes and grasses mature, the proportion of leaves to stems shifts away from leaves toward more stems. No. Mixing a TMR reduces the particle size of all feeds, and the length of time the ration is mixed can greatly influence particle size. 1Increase these rates for silage with dry matter density less than 14 lb/ft3 (bulk density less than 40 lb/ft3). The combination of low sugar content at harvest and high buffering capacity means alfalfa is especially prone to incomplete fermentation. When ensiling this mixture, harvest when the sudangrass is at early head to early bloom stages. Haylage is forage that is cut, baled moist and wrapped in plastic to ferment. Density = 10 to 14 pounds per cubic foot for hay Legume crops, such as alfalfa, contain relatively low levels of carbohydrates compared to corn silage and require field wilting to increase the concentration of carbohydrates and reduce moisture content in the forage mass. These products usually contain a combination of acids, including benzoic, sorbic, acetic, or citric acids, but propionic acid typically is the primary ingredient due to its excellent ability to inhibit the growth of yeast and molds. Chlorinated water may reduce the effectiveness of microbial inoculation, particularly when chlorine levels exceed 1.5 parts per million. Anhydrous ammonia is often the most economical source of ammonia or NPN. Research at The University of Wisconsin and Cornell identified a significant advantage for bunker silos with a density pack greater than 14 pounds of dry matter per cubic foot of silage.

How can the total weight of a loaded forage box be estimated? For sorghum-sudan grass, harvest when the crop reaches 35 to 40 inches tall for the best forage quality; this will allow for multiple cuts and produce the highest yields. Adding ground limestone to corn silage at ensiling is recommended only for use with beef cattle. The increased acidity of the forage mass enhances the growth and development of lactic acid-producing bacteria that convert plant carbohydrates to lactic acid, acetic acid, ethanol, mannitol, and carbon dioxide. Run the blower for 15 to 20 minutes before entering the silo, and while anyone is working in it, to evacuate gas. To pack silage safely, keep a respectable distance from unsupported edges, use tractors with a rollover protection system, and wear a seat belt. Feeding strategies for high-nitrate forage include: Due to large variations in forage nitrate levels, it is important to retest forage periodically. It also should have higher lactic acid levels and a lower pH. In Imperial or US customary measurement system, the density is equal to 49.32 pound per cubic foot [lb/ft], or 0.457 ounce per cubic inch [oz/inch] . Table 10. Goggles and rubber gloves are needed to provide eye and skin protection when connecting ammonia hoses and fittings. At the boot stage, forage yield is greater than any previous stage, and the whole plant is very leafy and highly digestible. Also inspect hydraulic hoses and fittings; replace any that are leaking, stiff, cracked, or have a soft or blistered cover. Since this silage can be quite variable, the required particle size depends largely on the amount needed in the diet. However, if the time between chopping and ensiling exceeds 2 to 3 hours, inoculants should be added at the chopper. 0000028236 00000 n

If the mixer must operate while loading, add forages last. Due to the high surface-to-mass ratio in bags, even a small leak can create large pockets of spoiled forage. Silage: Field to Feedbunk. High levels of naturally occurring bacteria in silage make it difficult for inoculated bacteria to gain a competitive edge. Recommended removal rates are presented in Table 18. Therefore, the longer cut forage lies in the field, the greater respiration losses will be. Managing silage stacks or piles is similar to managing horizontal silos. Bushels = 0.314 x diameter x diameter x average depth of grain (all in feet) for ear corn, Bushels = width x length x average depth of grain (all in feet) x density (same values as previous), Bushels = Pi x diameter x diameter x depth of grain (all in feet) x density x (1 - % moisture) / .845, for number 2 shelled corn or ground ear corn It's not an everyday problem, but there will be times when you need to calculate the capacity of something. Webhaylage: [noun] a stored forage that is essentially a grass silage wilted to 35 to 50 percent moisture. Ammonia can decrease this protein degradation by 20 to 40 percent. 2Survey of research published in the United States from 1996 through July 2003. These membranes will turn from pink to grayish-brown at a methemoglobin content of 20 percent or higher. The latter accounts for the largest change. Connect with your County Extension Office , Find an Extension employee in our staff directory , Get the latest news and updates on Extension's work around the state, Feedback, questions or accessibility issues: info@extension.wisc.edu | 2023 The Board of Regents of the University of Wisconsin System Privacy Policy | Non-Discrimination Policy & How to File a Complaint | Disability Accommodation Requests. Include nitrate intake from all sources in total dietary intake. Maximum single meal dry matter intake of forages containing various levels of nitrate-nitrogen (NO3-N).1. Weight = gallons x pounds per gallon Dry matter yield of small grain forage as maturity advances. Tips useful in hot weather include: feed multiple times per day, limit wet ingredients in the ration, mix TMR for one feeding (do not mix ahead), and add a buffered propionic acid product or other mold inhibitor to the TMR where spoilage is a problem. Usually when the milk line has descended three-quarters to all the way down the corn kernel and reached the black layer stage, the moisture content is in the 55 to 60 percent range. Producers can decide late in the growing season how much corn to harvest as silage or as grain. In general, haylage has a moisture content of between 15 percent to a maximum of 40 percent (60 to 85 percent DM). To meet the guidelines presented in Table 4, it is necessary to test forage samples to determine moisture content prior to harvest. Considerable research has been conducted on the use of silage additives; however, due to the dynamic nature of silage fermentation, the results have been variable. As has been well documented by research, storage losses can range from below 5 percent to over 50 percent, depending on storage method. Due to the corrosive nature of propionic acid, it is often sold in buffered form, as a propionic salt. Table 11. Notice that yield is much greater at the soft dough stage, but silage nutrient composition is similar for boot and soft dough. From Harvest to Feed: Understanding Silage Management, Skip to the beginning of the images gallery, downloaded from the University of Wisconsin website, Effects of Calf Feeding Program on First Lactation Performance, Body Condition Scoring as a Tool for Dairy Herd Management, Colostrum Management Tools: Hydrometers and Refractometers. If harvest stretches out over an extended period, nutrient and moisture content can change drastically. Recommended moisture content of silage crops by storage structure. As legumes and grasses mature, the proportion of leaves to stems shifts away from leaves toward more stems. No. Mixing a TMR reduces the particle size of all feeds, and the length of time the ration is mixed can greatly influence particle size. 1Increase these rates for silage with dry matter density less than 14 lb/ft3 (bulk density less than 40 lb/ft3). The combination of low sugar content at harvest and high buffering capacity means alfalfa is especially prone to incomplete fermentation. When ensiling this mixture, harvest when the sudangrass is at early head to early bloom stages. Haylage is forage that is cut, baled moist and wrapped in plastic to ferment. Density = 10 to 14 pounds per cubic foot for hay Legume crops, such as alfalfa, contain relatively low levels of carbohydrates compared to corn silage and require field wilting to increase the concentration of carbohydrates and reduce moisture content in the forage mass. These products usually contain a combination of acids, including benzoic, sorbic, acetic, or citric acids, but propionic acid typically is the primary ingredient due to its excellent ability to inhibit the growth of yeast and molds. Chlorinated water may reduce the effectiveness of microbial inoculation, particularly when chlorine levels exceed 1.5 parts per million. Anhydrous ammonia is often the most economical source of ammonia or NPN. Research at The University of Wisconsin and Cornell identified a significant advantage for bunker silos with a density pack greater than 14 pounds of dry matter per cubic foot of silage.  Feedback, questions or accessibility issues: Making Sure Your Kernel Processor Is Doing Its Job, 2023 The Board of Regents of the University of Wisconsin System, Non-Discrimination Policy & How to File a Complaint. First, calculate the amount of N needed per ton by multiplying 0.15 by the silage dry matter content as a whole number. WebDensity = 10 to 14 pounds per cubic foot for hay Density = 6 to 8 pounds per cubic foot for straw Density = 10 to 12 pounds per cubic foot for corn stover Short version: Pounds = 0.0005787 x length x width x height (all in inches) x density 8. 50 (ft) x 30 (ft) x 12 (ft) = 18,000 cubic feet 18,000 cubic feet x 40 lb/cubic feet = 720,000 lb silage Density = 4 to 5 pounds per cubic foot for straw, Pounds = 3.1416 x ( diameter / 12) x ( diameter / 12) x (width / 12) (all in inches) x density Although some natural compaction occurs in deep horizontal silos, thorough mechanical packing is required to achieve adequate density and limit excess air infiltration. Ensiling generally reduces the risk of prussic acid poisoning after about 4 weeks. As a result, fiber and lignin levels in the whole plant increase, while protein and energy decrease (Figure 3). Previous How much space does a cow need in a shed that allows them to go in The actual chemical and physical characteristics of the plant material at harvest determine the outcome of using silage additives. Microbial inoculants may be more effective when corn is immature, overly dry, stressed by drought, or killed by frost. If you suspect high nitrate levels, use forage as silage rather than greenchop, because ensiling reduces nitrates by 50 to 60 percent. The site must drain away from the open end of the bag, and should be clean and weed-free to minimize rodent populations. Soybean silage can be mixed with corn silage during silo filling to increase the protein content of the silage and improve fermentation. 1If one forage contains over 0.44% NO3 or 1,000 ppm NO3-N, test all forages, water, and possibly concentrates. 0000006582 00000 n