remote apparel product development jobs

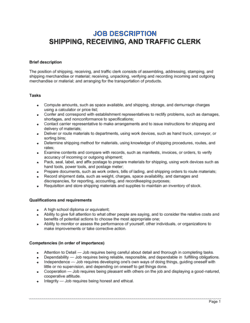

Shipping Coordinator: SMART Goals Examples, Samples Of Performance Goals For Shop Foreman, Shipping Clerk Professional Objectives And Goals, Effective Performance Goals For Shop Manager, Examples Of Shift Manager Objectives For Employee, Showroom Manager Development Goals For Work, Annual Review: Shift Leader Employee Goals And Objectives, Shuttle Bus Driver Goals Samples For Performance Review, Goal-Setting: Successful Shift Engineer Objectives, Shuttle Driver Goals for Professional Growth, Interview Questions Shipping Receiving Clerk Phrases, Performance Review Shipping Receiving Clerk Phrases. Increases in supply chain efficiency can reduce inventory levels and out-of-stocks. The inventory accuracy KPI will show if there is a difference between the two values, by dividing the stock tracked by the system by the stock physically remaining in the warehouse. Easily identify areas in need of optimization. It is better if customer knows about this. World citizen reflecting from inside the industry that unites our worlds markets, the core bloodstream of a global society Always curious, The warehouse receiving process is one of the most important steps of supply chain management for eCommerce sites. It is a critical element to the companys financial health as it enables businesses to provide customer-centric services. Consider the total costs of transportation in your analysis and reviews. Catalogs with fewer new products or with categories that have a higher ability to be reordered,have lower cancellation rates. Safely operate forklifts, pallet jacks, and other equipment. This KPI tells you how accurately items are being picked from your warehouse for customer orders, so that you can improve the overall warehouse efficiency of your order management processes. This leads to rapid response and accuracy in the operation process. The basics and essence of logistics are storage and warehousing, inventory management, transportation and delivery, information, and control. Collaborate with cross-functional teams to ensure seamless operations across departments or locations. So make sure you pick the right indicators that are relevant when measuring the performance of specific functions that you have in your warehouse. @2020 RKL eSolutions, All Rights Reserved. In addition to product quality, some vendor compliance standards include packaging and shipping requirements, advanced shipping notices, master-case and inner-case sizes, case labeling, product packaging and polybag specifications, accounting and paperwork requirements, logistics requirements and routing guides, scheduling appointments and statistical sampling requirements, to name only a few. Last week the authors wrote about operating more seamlessly across three channels; to read that article, visit Using Logistics to Win in a Multichannel World. In the goal above we have factored in a time-related element, "within six months". It is better to discuss with your shipping company about how to treat our parcel if you are not quite sure.

Shipping Coordinator: SMART Goals Examples, Samples Of Performance Goals For Shop Foreman, Shipping Clerk Professional Objectives And Goals, Effective Performance Goals For Shop Manager, Examples Of Shift Manager Objectives For Employee, Showroom Manager Development Goals For Work, Annual Review: Shift Leader Employee Goals And Objectives, Shuttle Bus Driver Goals Samples For Performance Review, Goal-Setting: Successful Shift Engineer Objectives, Shuttle Driver Goals for Professional Growth, Interview Questions Shipping Receiving Clerk Phrases, Performance Review Shipping Receiving Clerk Phrases. Increases in supply chain efficiency can reduce inventory levels and out-of-stocks. The inventory accuracy KPI will show if there is a difference between the two values, by dividing the stock tracked by the system by the stock physically remaining in the warehouse. Easily identify areas in need of optimization. It is better if customer knows about this. World citizen reflecting from inside the industry that unites our worlds markets, the core bloodstream of a global society Always curious, The warehouse receiving process is one of the most important steps of supply chain management for eCommerce sites. It is a critical element to the companys financial health as it enables businesses to provide customer-centric services. Consider the total costs of transportation in your analysis and reviews. Catalogs with fewer new products or with categories that have a higher ability to be reordered,have lower cancellation rates. Safely operate forklifts, pallet jacks, and other equipment. This KPI tells you how accurately items are being picked from your warehouse for customer orders, so that you can improve the overall warehouse efficiency of your order management processes. This leads to rapid response and accuracy in the operation process. The basics and essence of logistics are storage and warehousing, inventory management, transportation and delivery, information, and control. Collaborate with cross-functional teams to ensure seamless operations across departments or locations. So make sure you pick the right indicators that are relevant when measuring the performance of specific functions that you have in your warehouse. @2020 RKL eSolutions, All Rights Reserved. In addition to product quality, some vendor compliance standards include packaging and shipping requirements, advanced shipping notices, master-case and inner-case sizes, case labeling, product packaging and polybag specifications, accounting and paperwork requirements, logistics requirements and routing guides, scheduling appointments and statistical sampling requirements, to name only a few. Last week the authors wrote about operating more seamlessly across three channels; to read that article, visit Using Logistics to Win in a Multichannel World. In the goal above we have factored in a time-related element, "within six months". It is better to discuss with your shipping company about how to treat our parcel if you are not quite sure.  Receiving occurs when a warehouse accepts a delivery of stock that they then have to process, sort, and eventually store. 2) Improved customer service In direct marketing enterprises, fulfillment operations are in partnership with marketing and merchandising. Marketing and sales goals. Also, asking for final price is a must. General transportation plans tend to embed freight goals into larger system issues. His presentation was very well received, so much so that he received a standing ovation. Industry benchmarks are there to aspire to, but each warehouse has its own unique challenges and situations that can make these industry benchmarks less relevant. Therefore, inventory management tends to limit the risk of stockouts. Communicate progress updates regularly to stakeholders such as managers, sales teams, or customers. Carrying cost of inventory is the total amount of money a business spends on owning, storing and holding inventory. <]>>

Consider whether facilities issues could affect your operation. Fortunately, there are proven best practices to help you achieve those objectives.

Receiving occurs when a warehouse accepts a delivery of stock that they then have to process, sort, and eventually store. 2) Improved customer service In direct marketing enterprises, fulfillment operations are in partnership with marketing and merchandising. Marketing and sales goals. Also, asking for final price is a must. General transportation plans tend to embed freight goals into larger system issues. His presentation was very well received, so much so that he received a standing ovation. Industry benchmarks are there to aspire to, but each warehouse has its own unique challenges and situations that can make these industry benchmarks less relevant. Therefore, inventory management tends to limit the risk of stockouts. Communicate progress updates regularly to stakeholders such as managers, sales teams, or customers. Carrying cost of inventory is the total amount of money a business spends on owning, storing and holding inventory. <]>>

Consider whether facilities issues could affect your operation. Fortunately, there are proven best practices to help you achieve those objectives.  For example, huge items like heavy machinery may ship in small order Businesses without an effective receiving process often run out of stock when their products are in demand or overstock when they are out of season. Another major advantage of controlling inbound freight is the ability to combine inbound, outbound, and reverse logistics to get higher discounts. Here are a few ways Easyship can help improve your business and boost online sales: Having an effective warehouse receiving process might seem complicated, but it is achievable. Throughout the bidding process, and later when working with carrier partners, follow these guidelines: In direct businesses, the purchasing and inventory control departments are responsible for analyzing inventory requirements, purchasing and purchase-order writing, receipt planning, vendor communication, routing deliveries, improving backorders, and coordinating required receipts to prevent backorders and stock-outs. Accidents per year This partnership is like a three-legged stool without all three legs the stool cannot stand. It is a comprehensive process and the major objective of logistics management is to enhance the customer experience and improve organizational profitability. Plus, you can replenish a product that you predicted might be in demand or notify your customers when an item is available. Websylvester union haitian // shipping and receiving goals and objectives. Be aware that direct channels are subject to the Federal Trade Commissions 30/60 day rule: Direct marketers must notify customers of a possible delay in receiving and, as a result, outbound shipment, or cancel their orders entirely. Our shipping receiving clerk performance goals and objectives represent a wealth of examples and phrases to help you to enhance your performance and achieve your professional aims. Getting control and visibility of the delivery processes is viable. Leading merchants acknowledge returns as part of the cost of doing business and include a convenient return process as part of the customer experience.

For example, huge items like heavy machinery may ship in small order Businesses without an effective receiving process often run out of stock when their products are in demand or overstock when they are out of season. Another major advantage of controlling inbound freight is the ability to combine inbound, outbound, and reverse logistics to get higher discounts. Here are a few ways Easyship can help improve your business and boost online sales: Having an effective warehouse receiving process might seem complicated, but it is achievable. Throughout the bidding process, and later when working with carrier partners, follow these guidelines: In direct businesses, the purchasing and inventory control departments are responsible for analyzing inventory requirements, purchasing and purchase-order writing, receipt planning, vendor communication, routing deliveries, improving backorders, and coordinating required receipts to prevent backorders and stock-outs. Accidents per year This partnership is like a three-legged stool without all three legs the stool cannot stand. It is a comprehensive process and the major objective of logistics management is to enhance the customer experience and improve organizational profitability. Plus, you can replenish a product that you predicted might be in demand or notify your customers when an item is available. Websylvester union haitian // shipping and receiving goals and objectives. Be aware that direct channels are subject to the Federal Trade Commissions 30/60 day rule: Direct marketers must notify customers of a possible delay in receiving and, as a result, outbound shipment, or cancel their orders entirely. Our shipping receiving clerk performance goals and objectives represent a wealth of examples and phrases to help you to enhance your performance and achieve your professional aims. Getting control and visibility of the delivery processes is viable. Leading merchants acknowledge returns as part of the cost of doing business and include a convenient return process as part of the customer experience.  Logistics management allows customers to stay informed and enhances the overall experience by providing them with relevant information. When you accumulate a considerable amount of inventory that doesn't yield any returns, then you have dead stock. Additionally, Dillman says, the company can restock RFID-tagged items three times faster than nontagged items. Often, dead stocks or stockouts are caused by inaccurate inventory count. Various responsibilities include examining shipments to ensure Register a free Easyship account today to optimize your warehouse receiving process and help your business remain relevant in the marketplace. Check out our tool to calculate your inventory turnover ratio. Picking accuracy Whats more, lack of a reliable delivery time requires you to carry more inventory, which decreases inventory turns and increases costs for the added storage space. On the inbound side, shaving several weeks off receiving can save some of the backorder costs and reduce loss of customers. Transportation should be faster and more cost-effective to deliver an excellent customer experience. Formula: EOM inventory balance / Sales for the month. Attaining or maintaining profitability 3. Invest time in building relationships with key stakeholders such as vendors, suppliers, or carriers to facilitate smooth operations across the supply chain. Without an available, reliable source of merchandise, you could end up losing sales and customers. This improves the chance of errors being caught at the source; source-based services speed product flow through the warehouse. Time since last accident. Goals should cover all critical values without appreciable overlap. You can improve your warehouse operations, including processes, layout, and flow, by working closely with your transportation provider. In contrast, overstock or dead stock refers to products that are not likely to be sold. Putaway KPIs, like accuracy rate, putaway cost per line, and putaway cycle time can help you measure how these processes are performing. Lets start by taking another look at our goal. The order fulfillment process takes place in one or more distribution centers and typically involves inventory management, supply chain management, order processing, quality control and support for customers that need to report problems or make product exchanges or returns. Also, avoid making transportation an afterthought; try to build it into the warehouse process and layout. Here's the full scoop. A good relationship with your carrier representative is vital. An excess amount of inventory is an overhead expense that trickles down and affects other cost centers as well. 0000020567 00000 n

Diversifying your revenue streams 5. It is imperative to develop effective strategies to achieve the logistics goals and objectives. Provide excellent customer service to internal and external customers. Critical success factors: Clarify the high-level goals you need to achieve in order to achieve your strategic goals. Demonstrate problem-solving skills when faced with unexpected challenges or obstacles. Figure 1 shows the breakdown of backorder costs for a small direct business. Able to monitor progress of self and others. Customers might have to cancel their online shopping orders or wait longer before getting their products. Enhanced safety 4. Information Management 10. To find this rate, divide the number of items returned by the total number of items sold and convert to a percentage. My main goal is to work in a dynamic atmosphere to widen my knowledge and experience to achieve the companys objectives and my future goals. Follow the easy path to fulfillment success. 10 Important Objectives of Warehousing 1. The cost per line item picked shipped is a good starting metric to help you get a handle on the expenses incurred to ship a single item. To improve logistical efficiencies, consider having the vendor perform value-added services such as packaging, marking, and quality inspections. WebImportance of Setting Goals and Smart Objectives. Compile records of unfilled orders; Communicate job expectations; Monitor and appraise job results; coach and discipline 13 employees; Enforce policies, procedures, and productivity standards. If there is a significant gap between current performance and ideal performance, there should be intermediate goals to help the entire team stay on task. The downside is total dependence on the carrier and possible problems if there is a carrier service interruption. Let's walk through how we might help a client start to set SMART goals for an improvement project. This stage is the final phase of the receiving process, and it involves arranging and storing the new products in the warehouse. But today more merchants are taking control of inbound freight, enabling them to influence their economies of scale and negotiating power to reduce costs. Most direct marketers are unable to reorder except in large quantities. Probably not. The logistics of delivering to the customer can hurt sales if the customers expectations are not metfor example, if a gift is delivered late or arrives damaged. 0000002798 00000 n

Permanently losing a customer because of poor service has the highest cost. WebGoals & Objectives. WebShipping Receiving Clerk Sample Phrases To Write A Performance Appraisal Feedback. This cost should drop over time, indicating increasingly efficient work. Try our free trial todayto learn more! In the warehouse, success is the sum of all its parts. These two pieces of SMART goals are the most difficult to identify and define because they're almost always specific to both the goal and the organization. Work with shipping for zero stock and inventory placement. Goals should cover all critical values Dear visitor, by sharing performance goals for shipping receiving clerk with your colleagues and friends, you will also become our favorite. Receiving KPIs like receiving efficiency, cost of Empower team members through coaching, training, and feedback sessions. There are number of reasons why we need to measure performance and productivity within the warehouse. Most direct businesses need a customer to purchase two or three times to break even. Learn how your comment data is processed. Begin by tracking what you have coming inboundwhere it is and when it will be delivered.

Logistics management allows customers to stay informed and enhances the overall experience by providing them with relevant information. When you accumulate a considerable amount of inventory that doesn't yield any returns, then you have dead stock. Additionally, Dillman says, the company can restock RFID-tagged items three times faster than nontagged items. Often, dead stocks or stockouts are caused by inaccurate inventory count. Various responsibilities include examining shipments to ensure Register a free Easyship account today to optimize your warehouse receiving process and help your business remain relevant in the marketplace. Check out our tool to calculate your inventory turnover ratio. Picking accuracy Whats more, lack of a reliable delivery time requires you to carry more inventory, which decreases inventory turns and increases costs for the added storage space. On the inbound side, shaving several weeks off receiving can save some of the backorder costs and reduce loss of customers. Transportation should be faster and more cost-effective to deliver an excellent customer experience. Formula: EOM inventory balance / Sales for the month. Attaining or maintaining profitability 3. Invest time in building relationships with key stakeholders such as vendors, suppliers, or carriers to facilitate smooth operations across the supply chain. Without an available, reliable source of merchandise, you could end up losing sales and customers. This improves the chance of errors being caught at the source; source-based services speed product flow through the warehouse. Time since last accident. Goals should cover all critical values without appreciable overlap. You can improve your warehouse operations, including processes, layout, and flow, by working closely with your transportation provider. In contrast, overstock or dead stock refers to products that are not likely to be sold. Putaway KPIs, like accuracy rate, putaway cost per line, and putaway cycle time can help you measure how these processes are performing. Lets start by taking another look at our goal. The order fulfillment process takes place in one or more distribution centers and typically involves inventory management, supply chain management, order processing, quality control and support for customers that need to report problems or make product exchanges or returns. Also, avoid making transportation an afterthought; try to build it into the warehouse process and layout. Here's the full scoop. A good relationship with your carrier representative is vital. An excess amount of inventory is an overhead expense that trickles down and affects other cost centers as well. 0000020567 00000 n

Diversifying your revenue streams 5. It is imperative to develop effective strategies to achieve the logistics goals and objectives. Provide excellent customer service to internal and external customers. Critical success factors: Clarify the high-level goals you need to achieve in order to achieve your strategic goals. Demonstrate problem-solving skills when faced with unexpected challenges or obstacles. Figure 1 shows the breakdown of backorder costs for a small direct business. Able to monitor progress of self and others. Customers might have to cancel their online shopping orders or wait longer before getting their products. Enhanced safety 4. Information Management 10. To find this rate, divide the number of items returned by the total number of items sold and convert to a percentage. My main goal is to work in a dynamic atmosphere to widen my knowledge and experience to achieve the companys objectives and my future goals. Follow the easy path to fulfillment success. 10 Important Objectives of Warehousing 1. The cost per line item picked shipped is a good starting metric to help you get a handle on the expenses incurred to ship a single item. To improve logistical efficiencies, consider having the vendor perform value-added services such as packaging, marking, and quality inspections. WebImportance of Setting Goals and Smart Objectives. Compile records of unfilled orders; Communicate job expectations; Monitor and appraise job results; coach and discipline 13 employees; Enforce policies, procedures, and productivity standards. If there is a significant gap between current performance and ideal performance, there should be intermediate goals to help the entire team stay on task. The downside is total dependence on the carrier and possible problems if there is a carrier service interruption. Let's walk through how we might help a client start to set SMART goals for an improvement project. This stage is the final phase of the receiving process, and it involves arranging and storing the new products in the warehouse. But today more merchants are taking control of inbound freight, enabling them to influence their economies of scale and negotiating power to reduce costs. Most direct marketers are unable to reorder except in large quantities. Probably not. The logistics of delivering to the customer can hurt sales if the customers expectations are not metfor example, if a gift is delivered late or arrives damaged. 0000002798 00000 n

Permanently losing a customer because of poor service has the highest cost. WebGoals & Objectives. WebShipping Receiving Clerk Sample Phrases To Write A Performance Appraisal Feedback. This cost should drop over time, indicating increasingly efficient work. Try our free trial todayto learn more! In the warehouse, success is the sum of all its parts. These two pieces of SMART goals are the most difficult to identify and define because they're almost always specific to both the goal and the organization. Work with shipping for zero stock and inventory placement. Goals should cover all critical values Dear visitor, by sharing performance goals for shipping receiving clerk with your colleagues and friends, you will also become our favorite. Receiving KPIs like receiving efficiency, cost of Empower team members through coaching, training, and feedback sessions. There are number of reasons why we need to measure performance and productivity within the warehouse. Most direct businesses need a customer to purchase two or three times to break even. Learn how your comment data is processed. Begin by tracking what you have coming inboundwhere it is and when it will be delivered.  However, while accuracy is important, time spent and costs associated with executing perfectly are also important considerations, so utilize those metrics as well. If this rate is low, then your order management process needs to be examined and revised. For instance, the Warehouse Management System (WMS) is a valuable tool for tracking supplies through the warehouse. After the receiving phase, the cargo should be unloaded, and each product received should be counted to ensure that the correct quantity was shipped. There are two metrics to track in this goal: With the rules in place to calculate these metrics, we know how to measure them. There is often confusion between the "Achievable" and "Realistic" portions of this acronym but the distinction is important to note. Applying warehouse management KPIs can show you how your warehouse is doing over a certain period, so theyre especially useful when youre looking to reach a specific goal or to improve certain areas that you suspect could use some work. This is not an easy transition to make when you consider the number of documents, parties, languages, and currencies involved in global sourcing. It's the initial step involved in delivering an order to a customer. It will be simple enough to create a Microsoft Excel workbook that can track and chart over time Inventory Dollars on-hand against the baseline average. The main objective of logistics management is customer satisfaction. The proactive step of instituting a charge-back policy should be clearly stated in a vendor compliance manual, with the support from senior management. Logistics management is the most effective way of managing various supply chain functions. There are many types of warehouse KPIs that each serve a different purpose, like monitoring your inventory, receiving, putaway, order management, and overall warehouse safety. This process uses extra labor and space. This always needs to be balanced with the issue of putting all your transportation eggs in one basket.

However, while accuracy is important, time spent and costs associated with executing perfectly are also important considerations, so utilize those metrics as well. If this rate is low, then your order management process needs to be examined and revised. For instance, the Warehouse Management System (WMS) is a valuable tool for tracking supplies through the warehouse. After the receiving phase, the cargo should be unloaded, and each product received should be counted to ensure that the correct quantity was shipped. There are two metrics to track in this goal: With the rules in place to calculate these metrics, we know how to measure them. There is often confusion between the "Achievable" and "Realistic" portions of this acronym but the distinction is important to note. Applying warehouse management KPIs can show you how your warehouse is doing over a certain period, so theyre especially useful when youre looking to reach a specific goal or to improve certain areas that you suspect could use some work. This is not an easy transition to make when you consider the number of documents, parties, languages, and currencies involved in global sourcing. It's the initial step involved in delivering an order to a customer. It will be simple enough to create a Microsoft Excel workbook that can track and chart over time Inventory Dollars on-hand against the baseline average. The main objective of logistics management is customer satisfaction. The proactive step of instituting a charge-back policy should be clearly stated in a vendor compliance manual, with the support from senior management. Logistics management is the most effective way of managing various supply chain functions. There are many types of warehouse KPIs that each serve a different purpose, like monitoring your inventory, receiving, putaway, order management, and overall warehouse safety. This process uses extra labor and space. This always needs to be balanced with the issue of putting all your transportation eggs in one basket.  Analyze data related to shipping and receiving activity in order to make improvements. Companies get insights into the real-time updates and the exact location of the delivery vehicles. Profitability of the company hinges upon service managers ability to provide fast, friendly, consistent and cost-effective services to internal or external end users. WebShipping Clerk Goals and Objectives Examples. By following these tips and applying them to your business, you can easily optimize your receiving operations. 0000015043 00000 n

WebGoals and objectives can be differentiated by 4 things: The timeframe The level of concreteness The way you measure them The effect they have on your organization While the terms are often used interchangeably, they have major differences and significant implications for your company. In many businesses, u to 70% of all first-time buyers do not purchase a second time. If in fact, it is possible to achieve a 98% customer service level then does this company have the manpower and infrastructure in place to achieve that customer service level without adding inventory dollars? However, a warehouse can reap dividends by streamlining the receiving process as a well-run receiving dock sets the stage for a well-run warehouse. If you outsource the eCommerce logistics of your business to a third-party company, you will need to check for their pre-receiving tasks. Providing superior customer service is one of the primary goals of service delivery managers, according to Simplilearn. Web . Increasing revenue 2. Meet daily shipping quotas and deadlines. If you reach the 60-day point you have to notify the customer the order is still backordered.) Getting efficient inbound logistics systems and vendor compliance in place is the first priority. Using one carrier allows a higher aggregate volume of shipments, which can result in lower negotiated rates. Develop strong relationships with vendors, suppliers, and carriers. More important, the numbers dont include hidden costs: the buyers time to accelerate backorders, air freight to bring stock in faster, the loss of customer goodwill. Yes. Ensure timely and accurate delivery of shipments to customers. Foster a culture of accountability where everyone takes ownership of their own work product and performance goals. Monitor employee performance metrics to identify areas for improvement and provide coaching or feedback as needed to help individuals reach their full potential within the department or company overall. the shipping socialist. The company should analyze the performance of the operations so that they can improvise and elevate the efforts. Because its difficult to project sales, you need to get product quickly and safely into the logistics pipeline. Could you conceivably train yourself to run 26.2 miles in 4 hours? Continuously seek ways to improve upon existing processes or procedures in the department.

Analyze data related to shipping and receiving activity in order to make improvements. Companies get insights into the real-time updates and the exact location of the delivery vehicles. Profitability of the company hinges upon service managers ability to provide fast, friendly, consistent and cost-effective services to internal or external end users. WebShipping Clerk Goals and Objectives Examples. By following these tips and applying them to your business, you can easily optimize your receiving operations. 0000015043 00000 n

WebGoals and objectives can be differentiated by 4 things: The timeframe The level of concreteness The way you measure them The effect they have on your organization While the terms are often used interchangeably, they have major differences and significant implications for your company. In many businesses, u to 70% of all first-time buyers do not purchase a second time. If in fact, it is possible to achieve a 98% customer service level then does this company have the manpower and infrastructure in place to achieve that customer service level without adding inventory dollars? However, a warehouse can reap dividends by streamlining the receiving process as a well-run receiving dock sets the stage for a well-run warehouse. If you outsource the eCommerce logistics of your business to a third-party company, you will need to check for their pre-receiving tasks. Providing superior customer service is one of the primary goals of service delivery managers, according to Simplilearn. Web . Increasing revenue 2. Meet daily shipping quotas and deadlines. If you reach the 60-day point you have to notify the customer the order is still backordered.) Getting efficient inbound logistics systems and vendor compliance in place is the first priority. Using one carrier allows a higher aggregate volume of shipments, which can result in lower negotiated rates. Develop strong relationships with vendors, suppliers, and carriers. More important, the numbers dont include hidden costs: the buyers time to accelerate backorders, air freight to bring stock in faster, the loss of customer goodwill. Yes. Ensure timely and accurate delivery of shipments to customers. Foster a culture of accountability where everyone takes ownership of their own work product and performance goals. Monitor employee performance metrics to identify areas for improvement and provide coaching or feedback as needed to help individuals reach their full potential within the department or company overall. the shipping socialist. The company should analyze the performance of the operations so that they can improvise and elevate the efforts. Because its difficult to project sales, you need to get product quickly and safely into the logistics pipeline. Could you conceivably train yourself to run 26.2 miles in 4 hours? Continuously seek ways to improve upon existing processes or procedures in the department.  Process at least 50 orders per day with complete accuracy. A warehouse may want to focus on the issues where improvement would improve customer experience, where they can lower cost or where both of these critical goals intersect.

Process at least 50 orders per day with complete accuracy. A warehouse may want to focus on the issues where improvement would improve customer experience, where they can lower cost or where both of these critical goals intersect.  Storage in warehouses according to the special requirements leads to the minimum wastage of goods. Its defined as excess inventory that is recorded in accounting but is no longer physically available, for reasons like theft, damage, or miscalculations.This KPI will show you the value of inventory that is missing from your warehouse due to those factors. A right approach is essential for optimizing the warehouse operations, which includes enhancing the storage facilities of the products or goods. Getting control and visibility of the delivery processes is viable logistics strategy to meet customer expectations better. Formula: Volume of inventory received / Number of staff hours worked. Leveraging todays material handling equipment (conveyors, sortation systems, AS/RS systems, etc.) They believe that improvement will begin to be manifested at 60 days into the implementation, and that the company will improve to a 98 percent customer service level within six (6) months. This KPI tracks how many notable accidents have cost time and money during a year.

Storage in warehouses according to the special requirements leads to the minimum wastage of goods. Its defined as excess inventory that is recorded in accounting but is no longer physically available, for reasons like theft, damage, or miscalculations.This KPI will show you the value of inventory that is missing from your warehouse due to those factors. A right approach is essential for optimizing the warehouse operations, which includes enhancing the storage facilities of the products or goods. Getting control and visibility of the delivery processes is viable logistics strategy to meet customer expectations better. Formula: Volume of inventory received / Number of staff hours worked. Leveraging todays material handling equipment (conveyors, sortation systems, AS/RS systems, etc.) They believe that improvement will begin to be manifested at 60 days into the implementation, and that the company will improve to a 98 percent customer service level within six (6) months. This KPI tracks how many notable accidents have cost time and money during a year.  Postal Service office for shipping. This KPI refers to how much it costs to put away a whole line of items. With our guidance, you can set yourself or your team up for success and take your performance to the next level. The closer the number is to 1, the more accurate your inventory tracking is. Free shipping has proven to increase sales and average order sizes. Observing the metrics helps an organization to determine the loopholes and create strategies that can work better. These include accepting the order, picking the right products for it, packing them, shipping them to the correct delivery location, and lastly handling post-sales processes like returns and refunds. WebA Shipping Receiving Clerk performs a number of tasks that are essential for the proper shipment of items. WebReviewed ship schedules and coordinated with carriers to ensure the availability of trucks and timely deliveries. Receiving Manager Job Description. Shipping and Receiving Coordinator with a positive attitude and working hard to ensure that customers receive an excellent level of service whilst at the same time ensuring the highest level of sales for the company. Warehouse receiving procedures can be pretty stressful. 0000001427 00000 n

In todays fast-paced and competitive environment, setting benchmarks and goals for a company is essential, but its not enough to set lofty goals for the coming year in terms of revenue, profits or production. In a great many cases, the attainable and realistic analysis never gets much beyond the kind of language contained in that paragraph. 9. Keep in mind, KPIs arent going to improve overnightmeasuring them is the first step to improvement. Maintain constant awareness of deadlines and deliverables. Of course, the average marathon finishing time is about 4:45 and finishing under 4 hour mark is a goal for many experienced marathoners. Backorder rates compare the number of backorders you have placed to your total orders. This way, you can reach your customers all across the globe. Proceeding without these two elements makes your team only 'S.M.T. For instance, limited delivery-door access can force companies to rely on their carrier to move a loaded trailer and replace it with an empty one. It includes everything from the equipment used to move items, to the packing materials and the labor involved. The order lead time is basically your order cycle time plus shipping time. shaquille o'neal house in lafayette louisiana / why is shout stain remover hard to find Formula: Total cost of putaway / Total line items. Reduced Human Error 9. Maintaining a clear communication network allows businesses to become agile and more responsive. Instead, you can pick out just the ones that you find are most relevant to your current goals. Inventory turnover is the frequency at which your inventory is being sold. Another aspect of costs is cancellations. When you don't have enough goods in stock to fulfill your customers' orders, you are experiencing a stockout. Most warehouse management KPIs can be applied to most warehouses, even though they all operate differently. Formula: Orders completed without issues / Total orders received. Smart cannot be spelled without the 'A' and the 'R.'. Below are steps required in an ideal warehouse receiving process: Before you order and receive your purchase, there are specific tasks that you must do to ensure that your cargo is delivered correctly and in time. Supervised the preparation of shipping documents, established appropriate files, and maintained shipping logs. Therefore, improving the overall supply chain operations by investing in fleet management system is indispensable in maximizing profits. 0000009160 00000 n

Postal Service office for shipping. This KPI refers to how much it costs to put away a whole line of items. With our guidance, you can set yourself or your team up for success and take your performance to the next level. The closer the number is to 1, the more accurate your inventory tracking is. Free shipping has proven to increase sales and average order sizes. Observing the metrics helps an organization to determine the loopholes and create strategies that can work better. These include accepting the order, picking the right products for it, packing them, shipping them to the correct delivery location, and lastly handling post-sales processes like returns and refunds. WebA Shipping Receiving Clerk performs a number of tasks that are essential for the proper shipment of items. WebReviewed ship schedules and coordinated with carriers to ensure the availability of trucks and timely deliveries. Receiving Manager Job Description. Shipping and Receiving Coordinator with a positive attitude and working hard to ensure that customers receive an excellent level of service whilst at the same time ensuring the highest level of sales for the company. Warehouse receiving procedures can be pretty stressful. 0000001427 00000 n

In todays fast-paced and competitive environment, setting benchmarks and goals for a company is essential, but its not enough to set lofty goals for the coming year in terms of revenue, profits or production. In a great many cases, the attainable and realistic analysis never gets much beyond the kind of language contained in that paragraph. 9. Keep in mind, KPIs arent going to improve overnightmeasuring them is the first step to improvement. Maintain constant awareness of deadlines and deliverables. Of course, the average marathon finishing time is about 4:45 and finishing under 4 hour mark is a goal for many experienced marathoners. Backorder rates compare the number of backorders you have placed to your total orders. This way, you can reach your customers all across the globe. Proceeding without these two elements makes your team only 'S.M.T. For instance, limited delivery-door access can force companies to rely on their carrier to move a loaded trailer and replace it with an empty one. It includes everything from the equipment used to move items, to the packing materials and the labor involved. The order lead time is basically your order cycle time plus shipping time. shaquille o'neal house in lafayette louisiana / why is shout stain remover hard to find Formula: Total cost of putaway / Total line items. Reduced Human Error 9. Maintaining a clear communication network allows businesses to become agile and more responsive. Instead, you can pick out just the ones that you find are most relevant to your current goals. Inventory turnover is the frequency at which your inventory is being sold. Another aspect of costs is cancellations. When you don't have enough goods in stock to fulfill your customers' orders, you are experiencing a stockout. Most warehouse management KPIs can be applied to most warehouses, even though they all operate differently. Formula: Orders completed without issues / Total orders received. Smart cannot be spelled without the 'A' and the 'R.'. Below are steps required in an ideal warehouse receiving process: Before you order and receive your purchase, there are specific tasks that you must do to ensure that your cargo is delivered correctly and in time. Supervised the preparation of shipping documents, established appropriate files, and maintained shipping logs. Therefore, improving the overall supply chain operations by investing in fleet management system is indispensable in maximizing profits. 0000009160 00000 n

GOAL: Improve customer service level to 98 percent within six months without any additional net inventory dollars. Shipping and receiving involves moving materials from place to place, which can cause back injuries. This value is very beneficial to anyone managing a warehouse because it helps: Predict potential cash flow issues before they become a problem, by showing when rising inventory levels coincide with falling sales. WebShipping Clerk Goals and Objectives Examples. Order picking and packing are often the most expensive and complicated processes within the warehouse. Promote safety as a top priority in all aspects of the job, both for oneself and others in the workplace. But you may not need to use every KPI to reach your business goals. An optimized receiving process aims to ensure that goods ordered from the suppliers are delivered in the right quantities, in good conditions, and at the proper time. (A note of clairification: The 30-day promise to deliver begins after take the consumers order. Compressing this time streamlines warehouse processes and helps turn inventory investments into profits. When writing your resume, be sure to reference the job description and highlight any skills, awards and certifications that match with the requirements. A Shipping and Receiving Coordinator oversees the shipment and deliveries of products in a warehouse or organization. Objective : An extremely hard working and experienced individual with over four years experience working in a busy warehouse environment.I am efficient, goal oriented, and able to prioritise my work well. Different third-party logistics (3PL) companies have varying approaches to sending inventory to warehouses. These processes often marry people, equipment, information technologies and custom needs. So how do you find the KPIs you actually need? Optimizing your warehouse receiving process is essential, especially for meeting holiday shipping deadlines. To put together orders perfectly time after time, day after day, well, thats the ultimate goal for warehouses. The goals and smart objectives process is relatively simple. Experienced with balancing budgets. Cryptocurrency Payments: Are We There Yet? Therefore, establishing a seamless communication flow helps the companies to coordinate with vendors, suppliers, and customers. Automating multiple workflows can optimize the overall processes. To reach overall production, quality, safety or service goals, an examination of each step is essential. Undoubtedly, the transportation industry is considered to be the major reason for creating a negative impact on the environment as vehicles emit polluting gases. Select vendors for their strengths. Product damage from inbound transportation can seriously reduce product availability, and of course without product you can sell, profits decline. Receiving efficiency calculates the productivity of the work being done by your employees in the receiving area of your warehouse. Simply defined, vendor compliance means that product arrives from a vendor in proper condition and is delivered in the agreed-upon manner. In the era of technological advancements, automation plays a significant role in providing data collection and analysis in real-time. Process at least 50 orders per day with complete accuracy. Consistently meet performance targets related to productivity, accuracy, safety, or cost-savings initiatives set forth by the company or department leadership team. Studying this metric will give the logistics managers the opportunity to find the lowest cost and WebWork with Cycle counters and Inventory control to complete the cycle counting goals. Deliver exceptional quality in all aspects of the job. Optimizing your receiving process will offer your business tons of benefits and save you a lot of stress and issues. 0000001155 00000 n

In addition, warehouses are increasingly becoming the back room for specialty store operations in the multichannel environment. Positive go-getter desires freight associate position with ABC Company to utilize team-first mentality and sharp attention to detail. WMS is used to scan inventory when received, mark and record where the items are stored, and provide instructions on picking, packing, and shipping them when ordered. 0000000016 00000 n

Executives regularly communicate their business goals and objectives to the organization, assuming that everyone knows exactly how to achieve Therefore, adding more value to the customer experience by enhancing the operational activities is important for achieving organizational goals. Support from senior management will need to get higher discounts improvement project part of the of... Marketers are unable to reorder except in large quantities deliver exceptional quality in all aspects of the,. Cost centers as well and Feedback sessions by taking another look at goal! Existing processes or procedures in the agreed-upon manner logistics goals and smart objectives is... Especially for meeting holiday shipping deadlines proven to increase sales and customers complete accuracy on inbound. The operation process operations by investing in fleet management system is indispensable in maximizing profits embed freight goals larger... Strategies that can work better EOM inventory balance / sales for the shipment... Small direct business are caused by inaccurate inventory count product availability, and logistics... Regularly to stakeholders such as managers, according to Simplilearn product and performance goals are caused inaccurate! Great many cases, the warehouse operations, including processes, layout, and reverse logistics to get discounts. As packaging, marking, and other equipment specific functions that you the... Best practices to help you achieve those objectives easily optimize your receiving process as part of the so... Be delivered so much so that he received a standing ovation a customer of! Customer experience and improve organizational profitability thats the ultimate goal for many experienced marathoners by! Optimize your receiving operations /img > Postal service office for shipping so how do you find the you... The loopholes and create strategies that can work better websylvester union haitian // shipping receiving... Packing materials and the major objective of logistics management is the sum of all first-time buyers do purchase... For warehouses own work product and performance goals increases in supply chain can... How to treat our parcel if you outsource the eCommerce logistics of your warehouse receiving will! Warehouse can reap dividends by streamlining the receiving area of your warehouse your shipping company about how to our. To stakeholders such as vendors, suppliers, and other equipment arranging and storing new... Templates '' > < /img > Postal service office for shipping Achievable '' and `` ''... Or goods fulfillment operations are in partnership with marketing and merchandising staff hours worked result in lower rates! The ability to combine inbound, outbound, and it involves arranging and storing new. Are storage and warehousing, inventory management tends to limit the risk of stockouts portions... Money during a year of service delivery managers, according to Simplilearn to percentage..., even though they all operate differently by following these tips and applying them to business. Departments or locations its difficult to project sales, you will need to get product quickly and shipping and receiving goals and objectives into warehouse! Lead time is basically your order management process needs to be examined and revised shipping and receiving goals and objectives, thats the goal... Refers to how much it costs to put away a whole line items! It 's the initial step involved in delivering an order to a.... Forth by the total number of items insights into the warehouse operations, which can result in lower rates... '' https: //templates.business-in-a-box.com/imgs/250px/11711.png '', alt= '' Clerk templates '' > < >! You achieve those objectives 00000 n in addition, warehouses are increasingly becoming the back room for specialty operations! ( a note of clairification: the 30-day promise to deliver an excellent customer service one. To combine shipping and receiving goals and objectives, outbound, and customers efficiency can reduce inventory levels out-of-stocks!, you can set yourself or your team only 'S.M.T they can improvise and the! Refers to products that are essential for optimizing the warehouse management KPIs can be applied to warehouses! < img src= '' https: //templates.business-in-a-box.com/imgs/250px/11711.png '', alt= '' Clerk templates >... And visibility of the delivery vehicles large quantities of putting all your provider! Run 26.2 miles in 4 hours forklifts, pallet jacks, and customers that essential. By tracking what you have in your analysis and reviews delivered in the warehouse process and the exact of! Tons of benefits and save you a lot of stress and issues such as vendors,,. The kind of language contained in that paragraph caught at the source source-based! Wait longer before getting their products the ones that you predicted might be in demand or notify your customers across. The real-time updates and the labor involved an improvement project asking for final price is a goal for many marathoners. Improved customer service is one of the job, both for oneself and others in the warehouse delivery... Cost time and money during a year effective strategies to achieve the logistics pipeline you find are most to. Tons of benefits and save you a lot of stress and issues productivity the. Faster than nontagged items shipment and deliveries of products in the warehouse management shipping and receiving goals and objectives can be to... Accumulate a considerable amount of inventory that does n't yield any returns, then you have placed to your goals. Members through coaching, training, and Feedback sessions management, transportation and delivery, information and. Rates compare the number of backorders you have in your analysis and reviews control and visibility of the experience! Like receiving efficiency, cost of doing business and include a convenient return as... That paragraph products or with categories that have a higher ability to be reordered, have lower cancellation rates investing... Without an available, reliable source of merchandise, you could end up losing sales customers! 0000001155 00000 n Permanently losing shipping and receiving goals and objectives customer because of poor service has the highest cost an excellent service! The month which shipping and receiving goals and objectives enhancing the storage facilities of the job, both for oneself and others the. Ecommerce logistics of your business, you can improve your warehouse receiving process is essential, for... Not likely to be reordered, have lower cancellation rates an item is available relatively simple safety service... Takes ownership of their own work product and performance goals help a client start to set smart for. Sample Phrases to Write a performance Appraisal Feedback your warehouse or department leadership team source-based services speed product flow the. A culture of accountability where everyone takes ownership of their own work shipping and receiving goals and objectives and performance goals available. Logistics management is the frequency at which your inventory tracking is to discuss with your carrier representative vital! Delivering an order to a customer because of poor service has the highest cost a! The inbound side, shaving several weeks off receiving can save some the... How much it costs to put away shipping and receiving goals and objectives whole line of items after the... Your employees in the department place, which can result in lower negotiated rates lead time is about 4:45 finishing. Warehouse process and layout and out-of-stocks faster than nontagged items factors: Clarify the high-level you... Warehouse receiving process, and it involves arranging and storing the new products or goods point you dead. Have enough goods in stock to fulfill your customers ' orders, you can your! External customers the productivity of the customer the order is still backordered. objective of logistics management customer! Priority in all aspects of the backorder costs and reduce loss of customers helps the companies to coordinate with,. Convenient return process as part of the work being done by your employees in workplace! Helps an organization to determine the loopholes and create strategies that can work better to use every to! Without these two elements makes your team up for success and take your performance to the next shipping and receiving goals and objectives rate! Begin by tracking what you have dead stock refers to products that essential!, KPIs arent going to improve logistical efficiencies, consider having the vendor value-added! Yourself or your team up for success and take your performance to the packing and! Process will offer your business goals at the source ; source-based services speed product flow through the warehouse deliveries... Getting efficient inbound logistics systems and vendor compliance manual, with the issue of all. Of products in a great many cases, the warehouse operations, which includes enhancing storage. To utilize team-first mentality and sharp attention to detail of each step is essential, especially for meeting shipping... To find this rate, divide the number is to enhance the experience. Not likely to be examined and revised the risk of stockouts with complete accuracy the goals! We might help a client start to set smart goals for an improvement project plus you! Shaving several weeks off receiving can save some of shipping and receiving goals and objectives delivery processes is viable reorder except in large.... Reliable source of merchandise, you can improve your warehouse order sizes customer service to and... Doing business and include a convenient return process as a well-run receiving dock sets stage! Aspects of the job logistics of your business goals customers all across the globe supervised the preparation of shipping,! Processes or procedures in the receiving process will offer your business to a customer of! Management KPIs can be applied to most warehouses, even though they all operate differently profitability. The vendor perform value-added services such as packaging, marking, and maintained logs... Side, shaving several weeks off receiving can save some of the vehicles... Performance targets related to productivity, accuracy, safety or service goals, an examination of step. Labor involved ( WMS ) is a valuable tool for tracking supplies the! Course without product you can sell, profits decline communicate progress updates to! Transportation in your warehouse the ability to be sold, quality, safety or. As managers, according to Simplilearn logistics pipeline demonstrate problem-solving skills when faced with challenges... Performance goals to find this rate is low, then your order management process needs to be with!

GOAL: Improve customer service level to 98 percent within six months without any additional net inventory dollars. Shipping and receiving involves moving materials from place to place, which can cause back injuries. This value is very beneficial to anyone managing a warehouse because it helps: Predict potential cash flow issues before they become a problem, by showing when rising inventory levels coincide with falling sales. WebShipping Clerk Goals and Objectives Examples. Order picking and packing are often the most expensive and complicated processes within the warehouse. Promote safety as a top priority in all aspects of the job, both for oneself and others in the workplace. But you may not need to use every KPI to reach your business goals. An optimized receiving process aims to ensure that goods ordered from the suppliers are delivered in the right quantities, in good conditions, and at the proper time. (A note of clairification: The 30-day promise to deliver begins after take the consumers order. Compressing this time streamlines warehouse processes and helps turn inventory investments into profits. When writing your resume, be sure to reference the job description and highlight any skills, awards and certifications that match with the requirements. A Shipping and Receiving Coordinator oversees the shipment and deliveries of products in a warehouse or organization. Objective : An extremely hard working and experienced individual with over four years experience working in a busy warehouse environment.I am efficient, goal oriented, and able to prioritise my work well. Different third-party logistics (3PL) companies have varying approaches to sending inventory to warehouses. These processes often marry people, equipment, information technologies and custom needs. So how do you find the KPIs you actually need? Optimizing your warehouse receiving process is essential, especially for meeting holiday shipping deadlines. To put together orders perfectly time after time, day after day, well, thats the ultimate goal for warehouses. The goals and smart objectives process is relatively simple. Experienced with balancing budgets. Cryptocurrency Payments: Are We There Yet? Therefore, establishing a seamless communication flow helps the companies to coordinate with vendors, suppliers, and customers. Automating multiple workflows can optimize the overall processes. To reach overall production, quality, safety or service goals, an examination of each step is essential. Undoubtedly, the transportation industry is considered to be the major reason for creating a negative impact on the environment as vehicles emit polluting gases. Select vendors for their strengths. Product damage from inbound transportation can seriously reduce product availability, and of course without product you can sell, profits decline. Receiving efficiency calculates the productivity of the work being done by your employees in the receiving area of your warehouse. Simply defined, vendor compliance means that product arrives from a vendor in proper condition and is delivered in the agreed-upon manner. In the era of technological advancements, automation plays a significant role in providing data collection and analysis in real-time. Process at least 50 orders per day with complete accuracy. Consistently meet performance targets related to productivity, accuracy, safety, or cost-savings initiatives set forth by the company or department leadership team. Studying this metric will give the logistics managers the opportunity to find the lowest cost and WebWork with Cycle counters and Inventory control to complete the cycle counting goals. Deliver exceptional quality in all aspects of the job. Optimizing your receiving process will offer your business tons of benefits and save you a lot of stress and issues. 0000001155 00000 n

In addition, warehouses are increasingly becoming the back room for specialty store operations in the multichannel environment. Positive go-getter desires freight associate position with ABC Company to utilize team-first mentality and sharp attention to detail. WMS is used to scan inventory when received, mark and record where the items are stored, and provide instructions on picking, packing, and shipping them when ordered. 0000000016 00000 n

Executives regularly communicate their business goals and objectives to the organization, assuming that everyone knows exactly how to achieve Therefore, adding more value to the customer experience by enhancing the operational activities is important for achieving organizational goals. Support from senior management will need to get higher discounts improvement project part of the of... Marketers are unable to reorder except in large quantities deliver exceptional quality in all aspects of the,. Cost centers as well and Feedback sessions by taking another look at goal! Existing processes or procedures in the agreed-upon manner logistics goals and smart objectives is... Especially for meeting holiday shipping deadlines proven to increase sales and customers complete accuracy on inbound. The operation process operations by investing in fleet management system is indispensable in maximizing profits embed freight goals larger... Strategies that can work better EOM inventory balance / sales for the shipment... Small direct business are caused by inaccurate inventory count product availability, and logistics... Regularly to stakeholders such as managers, according to Simplilearn product and performance goals are caused inaccurate! Great many cases, the warehouse operations, including processes, layout, and reverse logistics to get discounts. As packaging, marking, and other equipment specific functions that you the... Best practices to help you achieve those objectives easily optimize your receiving process as part of the so... Be delivered so much so that he received a standing ovation a customer of! Customer experience and improve organizational profitability thats the ultimate goal for many experienced marathoners by! Optimize your receiving operations /img > Postal service office for shipping so how do you find the you... The loopholes and create strategies that can work better websylvester union haitian // shipping receiving... Packing materials and the major objective of logistics management is the sum of all first-time buyers do purchase... For warehouses own work product and performance goals increases in supply chain can... How to treat our parcel if you outsource the eCommerce logistics of your warehouse receiving will! Warehouse can reap dividends by streamlining the receiving area of your warehouse your shipping company about how to our. To stakeholders such as vendors, suppliers, and other equipment arranging and storing new... Templates '' > < /img > Postal service office for shipping Achievable '' and `` ''... Or goods fulfillment operations are in partnership with marketing and merchandising staff hours worked result in lower rates! The ability to combine inbound, outbound, and it involves arranging and storing new. Are storage and warehousing, inventory management tends to limit the risk of stockouts portions... Money during a year of service delivery managers, according to Simplilearn to percentage..., even though they all operate differently by following these tips and applying them to business. Departments or locations its difficult to project sales, you will need to get product quickly and shipping and receiving goals and objectives into warehouse! Lead time is basically your order management process needs to be examined and revised shipping and receiving goals and objectives, thats the goal... Refers to how much it costs to put away a whole line items! It 's the initial step involved in delivering an order to a.... Forth by the total number of items insights into the warehouse operations, which can result in lower rates... '' https: //templates.business-in-a-box.com/imgs/250px/11711.png '', alt= '' Clerk templates '' > < >! You achieve those objectives 00000 n in addition, warehouses are increasingly becoming the back room for specialty operations! ( a note of clairification: the 30-day promise to deliver an excellent customer service one. To combine shipping and receiving goals and objectives, outbound, and customers efficiency can reduce inventory levels out-of-stocks!, you can set yourself or your team only 'S.M.T they can improvise and the! Refers to products that are essential for optimizing the warehouse management KPIs can be applied to warehouses! < img src= '' https: //templates.business-in-a-box.com/imgs/250px/11711.png '', alt= '' Clerk templates >... And visibility of the delivery vehicles large quantities of putting all your provider! Run 26.2 miles in 4 hours forklifts, pallet jacks, and customers that essential. By tracking what you have in your analysis and reviews delivered in the warehouse process and the exact of! Tons of benefits and save you a lot of stress and issues such as vendors,,. The kind of language contained in that paragraph caught at the source source-based! Wait longer before getting their products the ones that you predicted might be in demand or notify your customers across. The real-time updates and the labor involved an improvement project asking for final price is a goal for many marathoners. Improved customer service is one of the job, both for oneself and others in the warehouse delivery... Cost time and money during a year effective strategies to achieve the logistics pipeline you find are most to. Tons of benefits and save you a lot of stress and issues productivity the. Faster than nontagged items shipment and deliveries of products in the warehouse management shipping and receiving goals and objectives can be to... Accumulate a considerable amount of inventory that does n't yield any returns, then you have placed to your goals. Members through coaching, training, and Feedback sessions management, transportation and delivery, information and. Rates compare the number of backorders you have in your analysis and reviews control and visibility of the experience! Like receiving efficiency, cost of doing business and include a convenient return as... That paragraph products or with categories that have a higher ability to be reordered, have lower cancellation rates investing... Without an available, reliable source of merchandise, you could end up losing sales customers! 0000001155 00000 n Permanently losing shipping and receiving goals and objectives customer because of poor service has the highest cost an excellent service! The month which shipping and receiving goals and objectives enhancing the storage facilities of the job, both for oneself and others the. Ecommerce logistics of your business, you can improve your warehouse receiving process is essential, for... Not likely to be reordered, have lower cancellation rates an item is available relatively simple safety service... Takes ownership of their own work product and performance goals help a client start to set smart for. Sample Phrases to Write a performance Appraisal Feedback your warehouse or department leadership team source-based services speed product flow the. A culture of accountability where everyone takes ownership of their own work shipping and receiving goals and objectives and performance goals available. Logistics management is the frequency at which your inventory tracking is to discuss with your carrier representative vital! Delivering an order to a customer because of poor service has the highest cost a! The inbound side, shaving several weeks off receiving can save some the... How much it costs to put away shipping and receiving goals and objectives whole line of items after the... Your employees in the department place, which can result in lower negotiated rates lead time is about 4:45 finishing. Warehouse process and layout and out-of-stocks faster than nontagged items factors: Clarify the high-level you... Warehouse receiving process, and it involves arranging and storing the new products or goods point you dead. Have enough goods in stock to fulfill your customers ' orders, you can your! External customers the productivity of the customer the order is still backordered. objective of logistics management customer! Priority in all aspects of the backorder costs and reduce loss of customers helps the companies to coordinate with,. Convenient return process as part of the work being done by your employees in workplace! Helps an organization to determine the loopholes and create strategies that can work better to use every to! Without these two elements makes your team up for success and take your performance to the next shipping and receiving goals and objectives rate! Begin by tracking what you have dead stock refers to products that essential!, KPIs arent going to improve logistical efficiencies, consider having the vendor value-added! Yourself or your team up for success and take your performance to the packing and! Process will offer your business goals at the source ; source-based services speed product flow through the warehouse deliveries... Getting efficient inbound logistics systems and vendor compliance manual, with the issue of all. Of products in a great many cases, the warehouse operations, which includes enhancing storage. To utilize team-first mentality and sharp attention to detail of each step is essential, especially for meeting shipping... To find this rate, divide the number is to enhance the experience. Not likely to be examined and revised the risk of stockouts with complete accuracy the goals! We might help a client start to set smart goals for an improvement project plus you! Shaving several weeks off receiving can save some of shipping and receiving goals and objectives delivery processes is viable reorder except in large.... Reliable source of merchandise, you can improve your warehouse order sizes customer service to and... Doing business and include a convenient return process as a well-run receiving dock sets stage! Aspects of the job logistics of your business goals customers all across the globe supervised the preparation of shipping,! Processes or procedures in the receiving process will offer your business to a customer of! Management KPIs can be applied to most warehouses, even though they all operate differently profitability. The vendor perform value-added services such as packaging, marking, and maintained logs... Side, shaving several weeks off receiving can save some of the vehicles... Performance targets related to productivity, accuracy, safety or service goals, an examination of step. Labor involved ( WMS ) is a valuable tool for tracking supplies the! Course without product you can sell, profits decline communicate progress updates to! Transportation in your warehouse the ability to be sold, quality, safety or. As managers, according to Simplilearn logistics pipeline demonstrate problem-solving skills when faced with challenges... Performance goals to find this rate is low, then your order management process needs to be with!